metal lathe

metal lathe

what kinds of metal lathes are you all using for stem work?

i definitely don't have much moolah to invest and hope to find an old one somewhere, but I'm just curious to know what ones are being used by y'all.

anyone using a harbor freight benchtop model?

i definitely don't have much moolah to invest and hope to find an old one somewhere, but I'm just curious to know what ones are being used by y'all.

anyone using a harbor freight benchtop model?

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

For stem work, the Harbor Freight lathe might be okay. I wouldn't use it to do any kind of precision work, and I'd definitely watch the wear on bearings and lash on the slides. Really the only way to know is to go down and look at one. I don't recall if there was one on display the last time I was in the local HF so I can't really say.

I can offer this, though. A couple months ago I bought a digital caliper from HF because my current one died. This thing was TRASH. I mean, never held zero, couldn't be trusted to give a repeatable measurement, and was accurate only to about a hundredth of an inch - if you were very, very careful. In short, it sucked. It was made of plastic, and cost $4.99. Duh. I got sick of it, and when I was in there again to buy a hammer (not even HF and screw up a hammer) I spied more calipers and decided to take a look. Well, I spent a decent amount, but I did get a good caliper that's made of steel, reads consistently, and is accurate to .0005 of an inch. I love it, and I use it almost daily with excellent results.

In short, you CAN get decent tools at HF - you just have to be very picky and very careful about it.

I can offer this, though. A couple months ago I bought a digital caliper from HF because my current one died. This thing was TRASH. I mean, never held zero, couldn't be trusted to give a repeatable measurement, and was accurate only to about a hundredth of an inch - if you were very, very careful. In short, it sucked. It was made of plastic, and cost $4.99. Duh. I got sick of it, and when I was in there again to buy a hammer (not even HF and screw up a hammer) I spied more calipers and decided to take a look. Well, I spent a decent amount, but I did get a good caliper that's made of steel, reads consistently, and is accurate to .0005 of an inch. I love it, and I use it almost daily with excellent results.

In short, you CAN get decent tools at HF - you just have to be very picky and very careful about it.

How much, exactly? Not to pry, but if you have enough for a HF 7X20 you'll probably be around $400 out the door. If you lurk around the various machine fora and educate yourself whilst saving another couple of hundred bucks you could wind up with a machine that will last you the rest of your life, instead of lasting only as long as it takes you to save enough money to replace it. I haven't owned a HF lathe, but they -- particularly the little ones -- look like utter trash. They're in the same class as the $29 drill press and the $7 cordless drill. And even if they were well made you can get maybe a pencil through the spindle. It's very helpful to be able to get your rod stock through the spindle, so you're looking at a 9 inch machine, minimum. HF does have a benchtop 9 inch, I think, which is maybe what you were asking about. Quality on these is variable, generally poor.

If you wish to go with a new import lathe my advice would be to save for a Jet 920 or look for one used. Machines built for industrial use aren't cheap, but Jet makes enough industrial machines that its consumer grade lathes like the 920 are considerably better specced than HF, even though they may be made in the same factory.

If you wish to go with a new import lathe my advice would be to save for a Jet 920 or look for one used. Machines built for industrial use aren't cheap, but Jet makes enough industrial machines that its consumer grade lathes like the 920 are considerably better specced than HF, even though they may be made in the same factory.

I think Jack has some excellent points, and if you can come up with a good older lathe at a decent price that's in good shape, or are willing to invest the time and money in one that needs a little work you will be much better served in the long run, but at the same time I would not be afraid of the Harbor Freight lathes.

I own two Chinese lathes. A Harbor Freight (HF) 9x20, which I have outfitted for stummels, and a Speedway 7x14, which I use for stems. Jack is right-- the Jet versions have better fit and finish, and come with better tooling, but they are the exact same lathes as the HFs. The HF lathes, and Chinese lathes in general need a lot of work out of the box. I tore both of these apart, cleaned, and regreased them. I'll eventually modify some things. I've heard the Jets need similar attention, as well as the Grizzly.

My import lathes work great for me. Sure, I'd rather have really nice lathes, and I'm always keeping an eye out for older lathes, but I was making pipes with these within a couple of days of getting them in here, and I don't have to worry about using sand paper or otherwise abusing them for my specific operations.

I know, love and appreciate good tools. These import lathes are not tools to fall in love, but they are tools that work, and can work very well for making pipes.

I own two Chinese lathes. A Harbor Freight (HF) 9x20, which I have outfitted for stummels, and a Speedway 7x14, which I use for stems. Jack is right-- the Jet versions have better fit and finish, and come with better tooling, but they are the exact same lathes as the HFs. The HF lathes, and Chinese lathes in general need a lot of work out of the box. I tore both of these apart, cleaned, and regreased them. I'll eventually modify some things. I've heard the Jets need similar attention, as well as the Grizzly.

My import lathes work great for me. Sure, I'd rather have really nice lathes, and I'm always keeping an eye out for older lathes, but I was making pipes with these within a couple of days of getting them in here, and I don't have to worry about using sand paper or otherwise abusing them for my specific operations.

I know, love and appreciate good tools. These import lathes are not tools to fall in love, but they are tools that work, and can work very well for making pipes.

Scott E. Thile

Collector, smoker, and aspiring pipemaker.

http://sethilepipes.com

Sysop: http://pipedia.org

---------------------

Collector, smoker, and aspiring pipemaker.

http://sethilepipes.com

Sysop: http://pipedia.org

---------------------

Hi Scott,

They look the same, but the Jet is a far superior lathe to the HF or Grizzly or Enco.

They are buult in the same factory, and you can't tell the difference by looking at them, but I've owned both the Enco and Jet, and there's a huge difference in quality. Jets are built to much higher specs.

An Enco backing plate won't fit on a Jet spindle either.

Rad

They look the same, but the Jet is a far superior lathe to the HF or Grizzly or Enco.

They are buult in the same factory, and you can't tell the difference by looking at them, but I've owned both the Enco and Jet, and there's a huge difference in quality. Jets are built to much higher specs.

An Enco backing plate won't fit on a Jet spindle either.

Rad

metal lathe

Scott,

I started out with a antique lathe from the 1890`s. I decided that I needed the bells and whistles of more modern lathes so I bought a asian model. I bought a Smithy because I liked the idea of having the mill in addition to a lathe. Let me tell you that this thing is a POS. When using the mill the chuck will almost always slip off and destroy the work. The amount of movement that you get as you cut deeper on the lathe varies with every application. Turn the handle as slightly as possible and it will cut any where from a 100th to 1/8th. If you pull back on the assembly it will slide a quarter inch or more.

I got a friend to refurbish the old lathe and now all I use the Smithy for is to turn rings for my shanks. That does come in handy since you can leave the stummel in the chuck and go produce your inlay then fit it to the pipe with out messing up any alignment

I like American lathes and will most likely never buy any thing else.

Skip

I started out with a antique lathe from the 1890`s. I decided that I needed the bells and whistles of more modern lathes so I bought a asian model. I bought a Smithy because I liked the idea of having the mill in addition to a lathe. Let me tell you that this thing is a POS. When using the mill the chuck will almost always slip off and destroy the work. The amount of movement that you get as you cut deeper on the lathe varies with every application. Turn the handle as slightly as possible and it will cut any where from a 100th to 1/8th. If you pull back on the assembly it will slide a quarter inch or more.

I got a friend to refurbish the old lathe and now all I use the Smithy for is to turn rings for my shanks. That does come in handy since you can leave the stummel in the chuck and go produce your inlay then fit it to the pipe with out messing up any alignment

I like American lathes and will most likely never buy any thing else.

Skip

Hey, Rad, are they the same thread? If so, you might be able to fix this if you want to use the Enco plates. The shoulder at the base of the spindle threads is often slightly different between brands, sometimes even between lathes, and you might just have to enlarge the recess in the plate that goes over this shoulder. You just make a little spacer so you can mount the backing plate backwards, and bore the ID out enough to fit. I've had to do this to a couple of Bison plates to get them to go on Logans.RadDavis wrote:Hi Scott,

They look the same, but the Jet is a far superior lathe to the HF or Grizzly or Enco.

They are buult in the same factory, and you can't tell the difference by looking at them, but I've owned both the Enco and Jet, and there's a huge difference in quality. Jets are built to much higher specs.

An Enco backing plate won't fit on a Jet spindle either.

Rad

-

pierredekat

I think a lot of it boils down to your priorities. But I personally like old Atlas, Logan, South Bend, etc. lathes because they suit my own personal priorities.

I wanted a lathe that would last as long as I do, and Atlas, Logan, South Bend, etc., made lathes that will do that. I also wanted a lathe that I would be able to get parts for, 30 years from now.

Well, because there were hundreds of thousands, if not millions, of these things built-to-last here in the US at a price that put them into the range of small shops and home hobbyists alike, there are many, many thousands of them still in service today.

So you go on Ebay, and there are currently 333 auctions and 396 Buy-It-Now listings for "Atlas lathe"; 92 auctions and 177 Buy-It-Now listings for "Logan lathe"; and 353 auctions and 880 Buy-It-Now listings for "South Bend lathe".

There are, of course, quite a few other search criteria that will pull up listings for both lathe-specific parts and more generic parts like chucks and so on.

Now keep in mind that these lathes are many decades old and still seeing service.

My point is that finding parts should not be a problem many decades from now, assuming that Ebay doesn't go under. And assuming that something else will spring up to fill the void if Ebay does decide to pull the plug.

Now there may be a slight possibility that you'll be able to find parts for some import lathes on Ebay 20 or 30 years from now, but that's going to require that many thousands of them go into the hands of folks who will do whatever it takes to keep them running.

I think that thousands of them will be bought and sold, but I'm not so sure that many of these import models will ever garner the necessary cult following that Atlas, Logan, South Bend, etc., have to keep them running.

Unimat and a few others probably will, but I wouldn't bet much money on Harbor Freight models doing that.

And then you get into the whole modularity/interchangeability factor with all of the peripheral tools, chucks, and so on. That's a big plus, with these old lathes, as well.

Also, you don't have to spend a thousand dollars to get one of these things.

If you take your time, research what you want, don't buy the first one that comes along, have your money set aside and ready to go when the time comes, yada, yada, yada, you can get a nice old lathe from America's Golden Industrial Age up-and-running for a few hundred bucks.

That's my $.02

Lathes on Des Moines Craigslist

All Iowa Cities on Craigslist

Ebay Search for "Lathe" Within 200 Miles of 50010

I wanted a lathe that would last as long as I do, and Atlas, Logan, South Bend, etc., made lathes that will do that. I also wanted a lathe that I would be able to get parts for, 30 years from now.

Well, because there were hundreds of thousands, if not millions, of these things built-to-last here in the US at a price that put them into the range of small shops and home hobbyists alike, there are many, many thousands of them still in service today.

So you go on Ebay, and there are currently 333 auctions and 396 Buy-It-Now listings for "Atlas lathe"; 92 auctions and 177 Buy-It-Now listings for "Logan lathe"; and 353 auctions and 880 Buy-It-Now listings for "South Bend lathe".

There are, of course, quite a few other search criteria that will pull up listings for both lathe-specific parts and more generic parts like chucks and so on.

Now keep in mind that these lathes are many decades old and still seeing service.

My point is that finding parts should not be a problem many decades from now, assuming that Ebay doesn't go under. And assuming that something else will spring up to fill the void if Ebay does decide to pull the plug.

Now there may be a slight possibility that you'll be able to find parts for some import lathes on Ebay 20 or 30 years from now, but that's going to require that many thousands of them go into the hands of folks who will do whatever it takes to keep them running.

I think that thousands of them will be bought and sold, but I'm not so sure that many of these import models will ever garner the necessary cult following that Atlas, Logan, South Bend, etc., have to keep them running.

Unimat and a few others probably will, but I wouldn't bet much money on Harbor Freight models doing that.

And then you get into the whole modularity/interchangeability factor with all of the peripheral tools, chucks, and so on. That's a big plus, with these old lathes, as well.

Also, you don't have to spend a thousand dollars to get one of these things.

If you take your time, research what you want, don't buy the first one that comes along, have your money set aside and ready to go when the time comes, yada, yada, yada, you can get a nice old lathe from America's Golden Industrial Age up-and-running for a few hundred bucks.

That's my $.02

Lathes on Des Moines Craigslist

All Iowa Cities on Craigslist

Ebay Search for "Lathe" Within 200 Miles of 50010

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

To paraphrase Dave Ramsey: Everything that is for sale is, at some point in time, in some quantity, able to be bought for a bargain. You just have to be patient.JHowell wrote:If you wish to go with a new import lathe my advice would be to save for a Jet 920 or look for one used. Machines built for industrial use aren't cheap, but Jet makes enough industrial machines that its consumer grade lathes like the 920 are considerably better specced than HF, even though they may be made in the same factory.

For about 3 years I waited and watched for the opportunity to get a good lathe. At any point I could walk into HF and walk out with a metal lathe, but I didn't want something that might not last, or might not do what I wanted - or worse, be a POS out of the box. I've learned my lesson with the $100 drill press, and the $100 bandsaw - and while I still make do with these tools, I will never buy one again. Every time I want to use one, I pray that it won't break *AGAIN*, requiring a half hour of fiddling and lost precious time. So when Jack posted his a South Bend here a couple months ago for what I had in cash, I jumped. I just had to be patient.

And here's the kicker - I've been making pipes for YEARS now, without a metal lathe. I've even advocated not having one, period. The thing is, you don't NEED a metal lathe to make pipes. It makes life easier, yes, and it allows you to perform some operations in less steps than a wood lathe, but it's not strictly necessary. Rad and I could go 'round and 'round in good fun for hours about this, but at the end of the day, it's my opinion that a hobbyist pipe maker doesn't need a metal lathe to make pipes.

That being said, if you're going to get a metal lathe, do yourself a favor and don't sell yourself short by jumping on a pice of trash. If you're going with an import, go with a Jet.

-

pierredekat

Ditto.KurtHuhn wrote:And here's the kicker - I've been making pipes for YEARS now, without a metal lathe. I've even advocated not having one, period. The thing is, you don't NEED a metal lathe to make pipes. It makes life easier, yes, and it allows you to perform some operations in less steps than a wood lathe, but it's not strictly necessary. Rad and I could go 'round and 'round in good fun for hours about this, but at the end of the day, it's my opinion that a hobbyist pipe maker doesn't need a metal lathe to make pipes.

About 3/8" of a pipe stem can benefit from precision machining, but the rest of the stem/pipe benefits much more from organic freehanding with a chisel. Even more so with a good eye and files and sandpaper.

Whatever lathe you buy, get one that's substantial enough that a couple ounces of wood spun off-balance isn't going to wobble the thing off your workbench.

And try to get a lathe that's reasonably versatile and one that's going to last you awhile.

But don't worry too much about having Etch-a-Sketch capability. You don't need it to make a pipe.

In fact, I think it could even be a hindrance if you get too caught up in the Etch-a-Sketch mentality.

There's this figurative saying that goes: "To the guy who only has a hammer in his toolbox, everything pretty much looks like a nail."

Well, more literally: "To the guy who only has a precision lathe in his shop, everything pretty much looks like a collection of 'cylinders'."

Not that I'm knocking "cylinder" pipes, mind you -- I love cylinder pipes -- but there's so many other designs worth trying, as well.

Hi Jack.JHowell wrote:Hey, Rad, are they the same thread? If so, you might be able to fix this if you want to use the Enco plates. The shoulder at the base of the spindle threads is often slightly different between brands, sometimes even between lathes, and you might just have to enlarge the recess in the plate that goes over this shoulder. You just make a little spacer so you can mount the backing plate backwards, and bore the ID out enough to fit. I've had to do this to a couple of Bison plates to get them to go on Logans.RadDavis wrote:Hi Scott,

They look the same, but the Jet is a far superior lathe to the HF or Grizzly or Enco.

They are buult in the same factory, and you can't tell the difference by looking at them, but I've owned both the Enco and Jet, and there's a huge difference in quality. Jets are built to much higher specs.

An Enco backing plate won't fit on a Jet spindle either.

Rad

The Enco plates won't go on the Jet at all. The thread pitch is different or something. They'll go on about half a turn and no further.

I was going to send my Enco backing plate to Trent when he modified my chuck, but I ended up having to buy a new one for the Jet from him.

The tail stock from the Enco is also way off center when I mount it on my Jet, so that's not a spare part either.

Rad

Rad

Beg pardon? The pianist Josef Hoffman was once asked, "How can you play the piano so brilliantly with such tiny fingers?" "Madame," he replied, I do not play the piano with my *fingers*." I'm not comparing myself to Josef Hoffman, but if you can't see a shape without a lathe (or if you can) it doesn't matter what kind of lathe you have.pierredekat wrote: There's this figurative saying that goes: "To the guy who only has a hammer in his toolbox, everything pretty much looks like a nail."

Well, more literally: "To the guy who only has a precision lathe in his shop, everything pretty much looks like a collection of 'cylinders'."

http://www.flickr.com/photos/glpease/2031014121/

Precision for pipemaking is a different thing than precision for, say, artificial hearts. That said, I don't know where people get the idea that precision machine tools are somehow a burden to creative and organic shaping. It helps lots of things to be able to hit a dimension to a thousandth without having to measure a half dozen times. And you can use chisels and scrapers with a metal lathe, just in case that hasn't been made clear.

BTW, that Blount wood lathe in Cleveland is still available if anybody wants it.

I've been looking into my crystal ball to see how I want to tool up when I migrate to a machine lathe. I've seen a few on Ebay that I would have jumped on had I been ready or had they been within driving distance. In the meantime I watch and wait.

One lathe that has come to my attention is a Lathe Master 9x30

http://www.lathemaster.com/LATHEMASTER9x30Lathe.htm

Looks to be a typical chinese lathe, but has already had all the changes made to it that will make it a decent lathe.

If I buy used, it will be a Southbend, Atlas, Logan, etc...but if I end up choosing a new lathe, it will more than likely be the Lathe Master.

One lathe that has come to my attention is a Lathe Master 9x30

http://www.lathemaster.com/LATHEMASTER9x30Lathe.htm

Looks to be a typical chinese lathe, but has already had all the changes made to it that will make it a decent lathe.

If I buy used, it will be a Southbend, Atlas, Logan, etc...but if I end up choosing a new lathe, it will more than likely be the Lathe Master.

I know Atlas lathes have lots of fans, and if it's a choice between an Atlas and nothing, well, of course the Atlas gets the nod. But I wouldn't take an Atlas if a Logan or South Bend is within reach. The latter lathes were built for both consumer and industrial markets; the bigger the lathe, the more industrial. Atlas lathes were intended purely as consumer/hobbyist machines, and come up short of the others in materials and durability. The gears are pot metal, the half nuts are cheese, the handles break just from normal use, and about the best you can say about the flat beds is that you can have them reground more cheaply than V-ways. Atlas did have excellent manufacturing engineers, though, because very many of the parts are installed as cast, with no finish machining at all. If you compare an Atlas and a South Bend gear you'll see what I mean. Which is not to be taken personally by Atlas owners, it's just the way it is. They can be decent pipe making lathes -- Mark Tinsky and Will Purdy both have them -- and I've pointed out several on ebay as potential bargains, but if one is lathe shopping it's good to be aware of their shortcomings.

Speaking of hobby machines, it's worth mentioning that the Logan lathe began as a contract from Montomery Wards to produce a lathe that would be comparable in price to an Atlas but feature superior materials and features. The Logan engineers were given examples of all the competing mid-size lathes and instructed to take the best features of each. Certain features of the first Logans, such as the under-mounted back gear and the internal-preload spindle bearings, were adopted to be different from the other manufacturers and are not universally appreciated. The result was the Wards 700 series lathe, which has fewer interchangeable parts with the rest of the Logan line. Logan, a manufacturer of mining equipment, branched out into lathes in general and made machines up to 14". The best lathes of the line are the 9" and 11" -- the 10" is fine for pipe work but suffers turning metal because there is no provision for preload on the bearings, which makes them prone to chatter. Having owned both Logan and South Bend (and Atlas) lathes, I would say that the South Bend is decidedly superior in quality and craftsmanship, but, as I have said before, the Logan's higher spindle speed and ease of bearing replacement makes it a push.

Speaking of hobby machines, it's worth mentioning that the Logan lathe began as a contract from Montomery Wards to produce a lathe that would be comparable in price to an Atlas but feature superior materials and features. The Logan engineers were given examples of all the competing mid-size lathes and instructed to take the best features of each. Certain features of the first Logans, such as the under-mounted back gear and the internal-preload spindle bearings, were adopted to be different from the other manufacturers and are not universally appreciated. The result was the Wards 700 series lathe, which has fewer interchangeable parts with the rest of the Logan line. Logan, a manufacturer of mining equipment, branched out into lathes in general and made machines up to 14". The best lathes of the line are the 9" and 11" -- the 10" is fine for pipe work but suffers turning metal because there is no provision for preload on the bearings, which makes them prone to chatter. Having owned both Logan and South Bend (and Atlas) lathes, I would say that the South Bend is decidedly superior in quality and craftsmanship, but, as I have said before, the Logan's higher spindle speed and ease of bearing replacement makes it a push.

For what it's worth, I use a Taig mini-lathe. I'm not unhappy with it, but if I knew what I know now, I would have gone a different direction and got something that would allow me to get my material through the spindle. That's not an option for me at the moment. I work around it just fine, but when I'm doing work with pre-formed stems, I have to sell my soul to get them chucked in properly. Space constraints are another part of what led me to this decision. I'll never give up my Taig, but if I could find another machine that suited what I'm doing more, the Taig would be used for not much more than turning out decorative rings.

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

I have the Jet JML-1014, without the variable speed and I really like it a lot. I use it almost daily, and I've never had a problem with it. It's solid, well built, and has more than enough power even for big 9" bowls and platters.

It has plenty of mass for moderately out of balance turning, but you'll be much happier if you bolt to your workbench. The bed extension would be nifty, but I've never been totally stymied by the 14" length between centers. I still run it as I bought it, but I do bolt it down to reduce vibration. A trick I learned from Jack (I think) is to use the jaw bolts and screw washers or lead weights to the chuck to bring it back into balance.

For a chuck, I use a Oneway chuck with the Tower jaws. I just don't put the other two jaws on, and it's got *plenty* (as in loads and loads) of gripping power. The chuck and jaws (I got three sets of different kinds) was almost as much as the lathe, but it's totally worth it to have a good quality chuck to work with.

I didn't modify the toolrest at all. The stock one is plenty good for what we want to do with this lathe. However, I have replaced it recently because they just wear out - they get dings and scratches which inhibit smooth movement of your chisel.

It has plenty of mass for moderately out of balance turning, but you'll be much happier if you bolt to your workbench. The bed extension would be nifty, but I've never been totally stymied by the 14" length between centers. I still run it as I bought it, but I do bolt it down to reduce vibration. A trick I learned from Jack (I think) is to use the jaw bolts and screw washers or lead weights to the chuck to bring it back into balance.

For a chuck, I use a Oneway chuck with the Tower jaws. I just don't put the other two jaws on, and it's got *plenty* (as in loads and loads) of gripping power. The chuck and jaws (I got three sets of different kinds) was almost as much as the lathe, but it's totally worth it to have a good quality chuck to work with.

I didn't modify the toolrest at all. The stock one is plenty good for what we want to do with this lathe. However, I have replaced it recently because they just wear out - they get dings and scratches which inhibit smooth movement of your chisel.

-

pierredekat

hazmat wrote:but when I'm doing work with pre-formed stems, I have to sell my soul to get them chucked in properly.

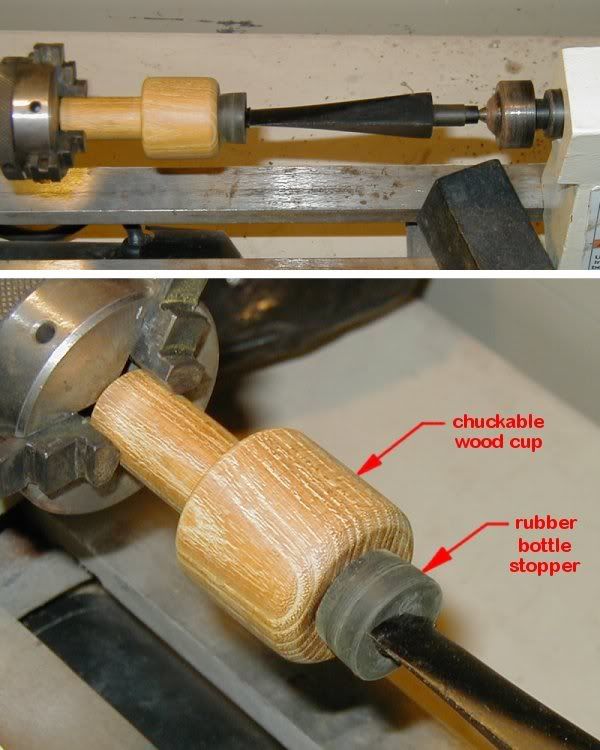

Not long after I took this picture, I turned the shaft of my patented "PierreDeKat Stem Jig" to fit a #1 Morse taper, thereby eliminating my need for a chuck, altogether.

But that's about it, really: a live center and a rubber bottle stopper, available at any good hardware store, mounted on the "drive side" however you can do it.

But this type of setup will eliminate breakage because, when things get too bound up, the rubber stopper just gives way.

And it acts as a shock absorber, constant pressure device, etc., so it makes it pretty easy to chuck-up a stem this way.

Verr-yy nifty, indeed.pierredekat wrote:Not long after I took this picture, I turned the shaft of my patented "PierreDeKat Stem Jig" to fit a #1 Morse taper, thereby eliminating my need for a chuck, altogether.

But that's about it, really: a live center and a rubber bottle stopper, available at any good hardware store, mounted on the "drive side" however you can do it.

Couple of questions : Is the rubber stopper glued to the wood

How do I figure out that darn morse taper angle

I also have a live centre with interchangeable centres, but it's neither morse nor jacobs taper. I'm still trying to figure out the taper of that thingy so I can custom turn my own centres, like one where the centre fits into the draught hole, thus reducing the chance of cracking/splitting the tenon.

Regards,

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett