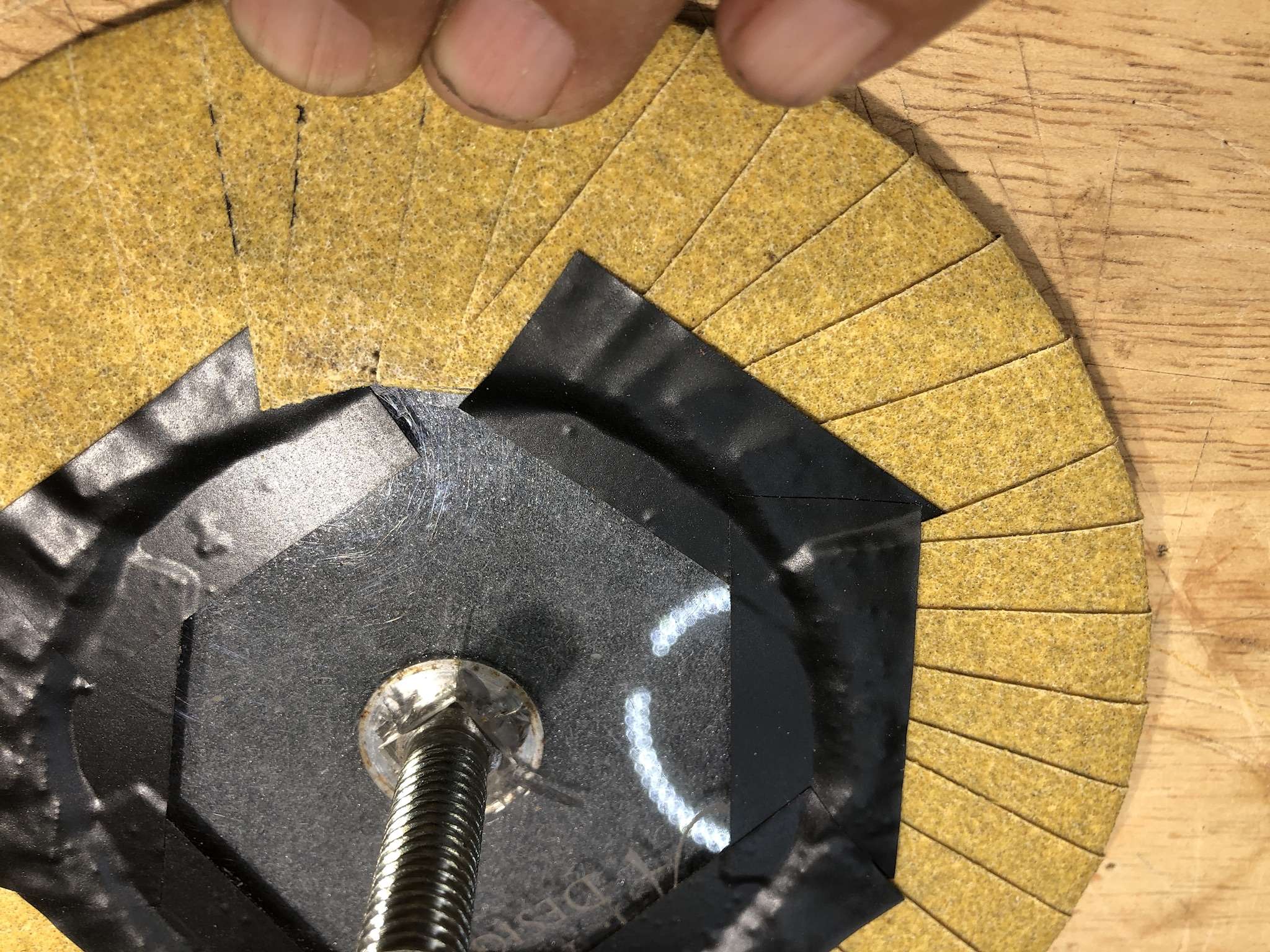

The completed tool. The big, wide diameter flange nut on the rear is necessary, as it turns out, to snug everything flush and true. If you use just a plain nut, it won't snug perpendicular to the bolt axis, and will wobble and be frustrating. I machined this nut from a scrap of aluminum rod I had laying around. The face is soft felt with an adhesive backing.

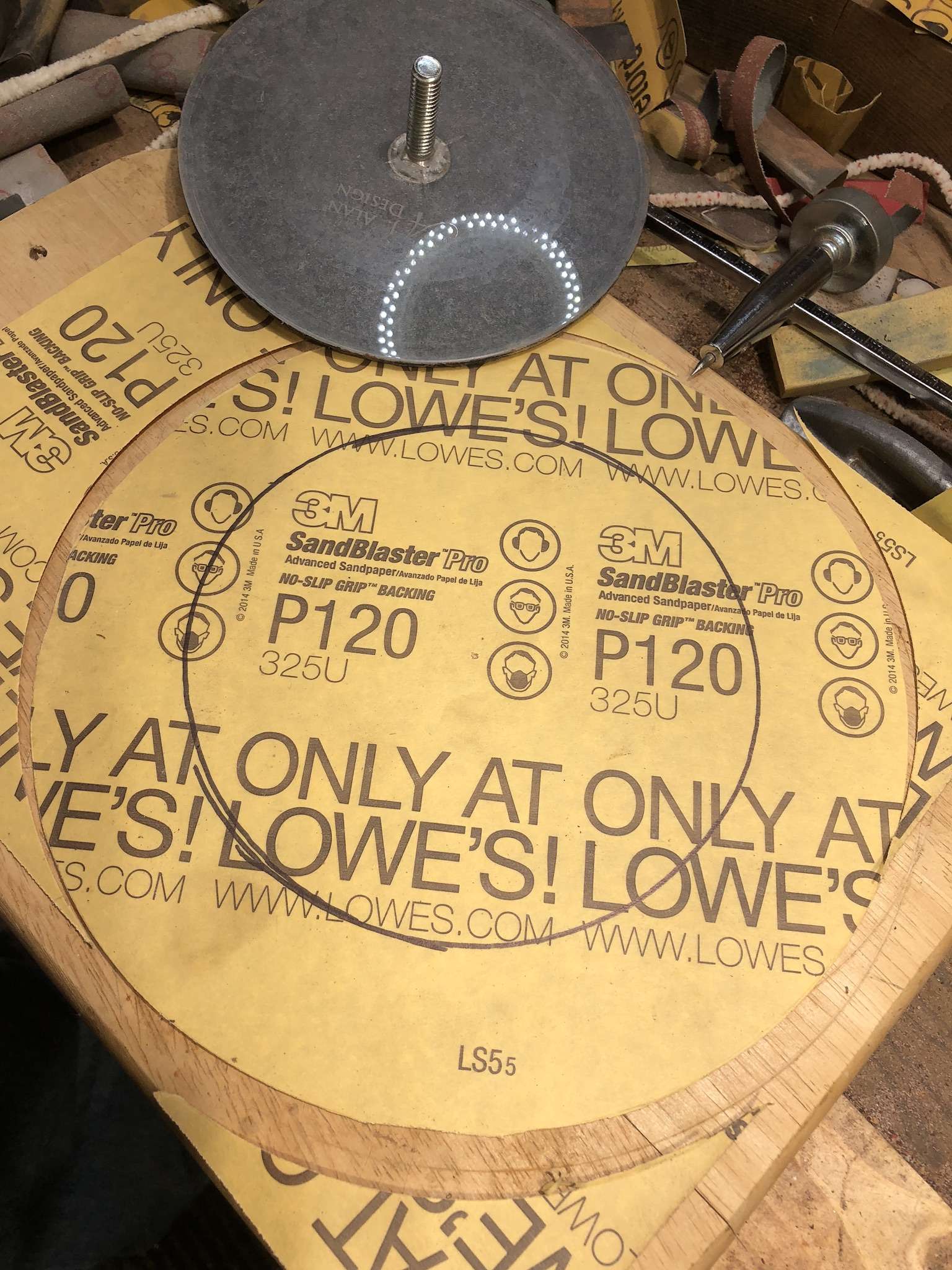

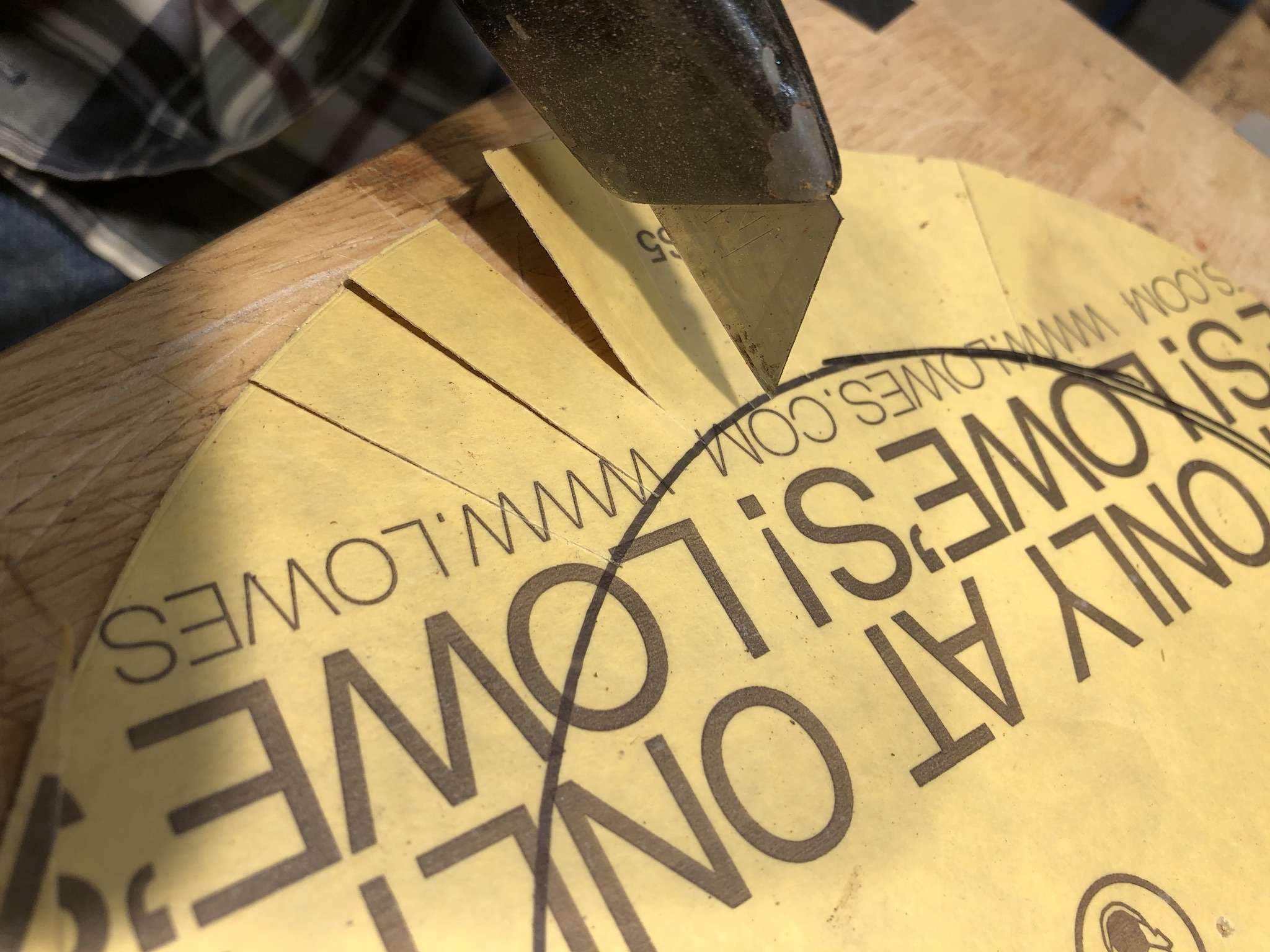

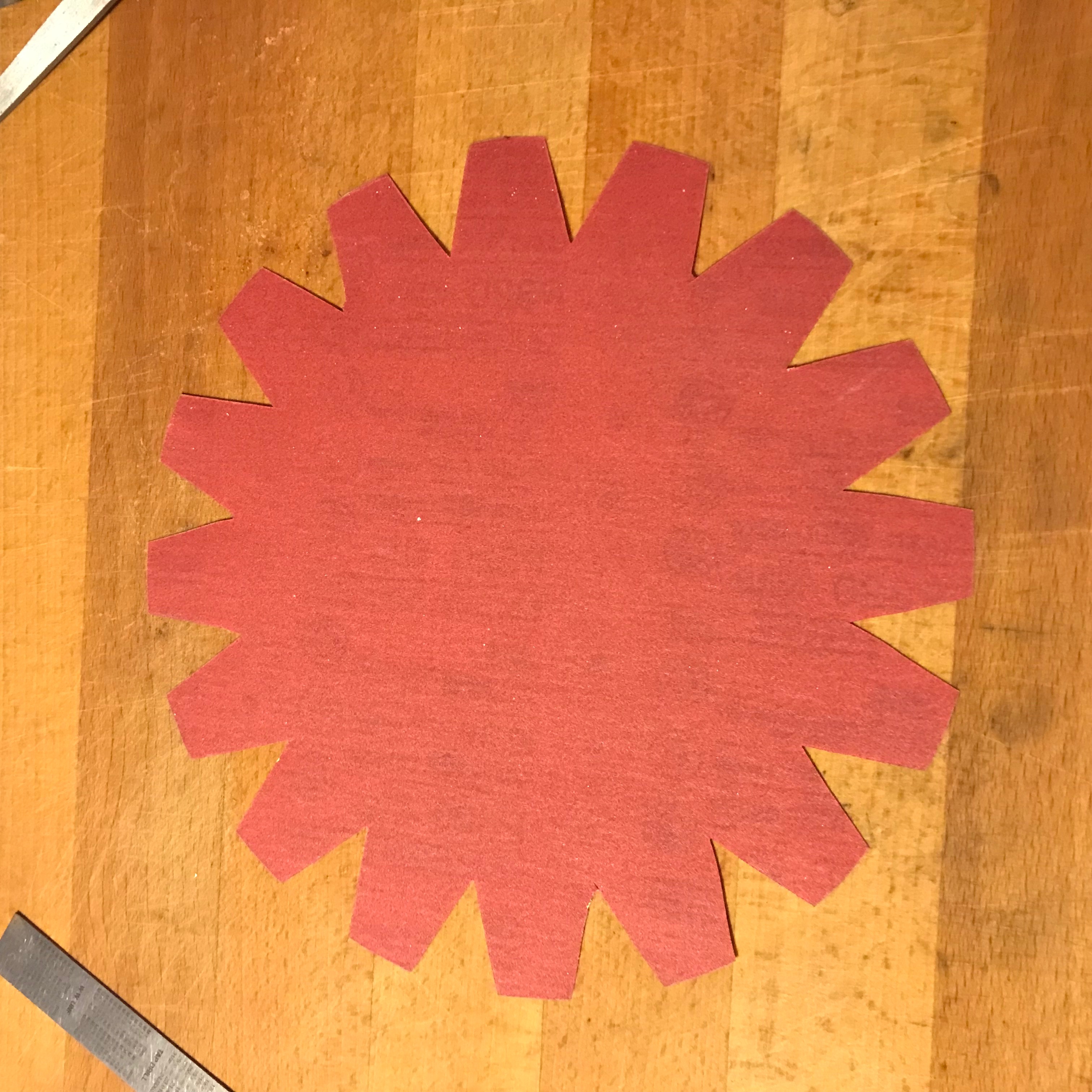

The sandpaper with tabs cut for folding over. I made a template in AutoCAD, which seemed to be the most time consuming part of this process:

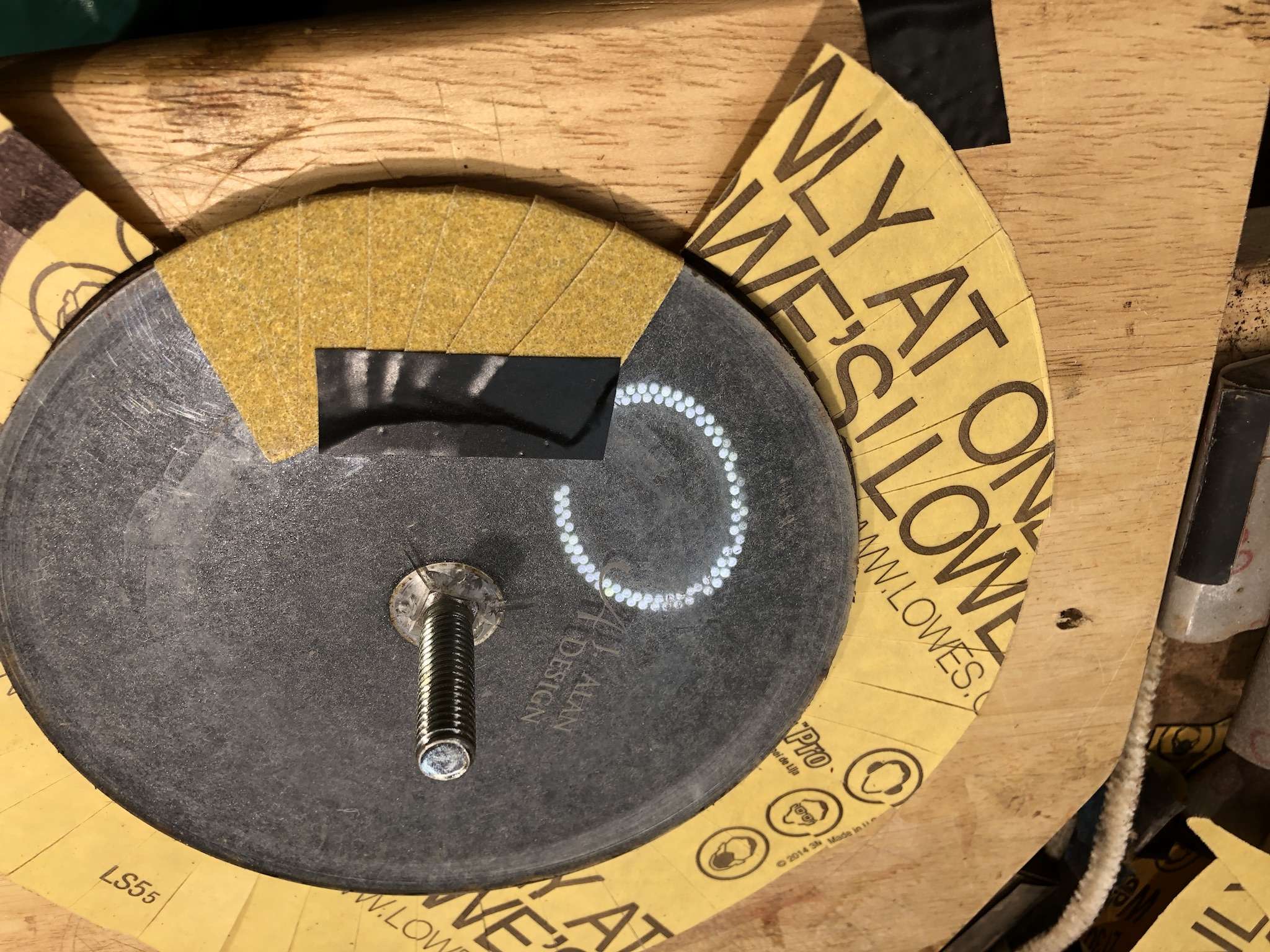

Tabs folded over, and everything looks pretty good.

And the wheel mounted on my motor/arbor:

I think I'm going to make another that will accept hook and loop discs, just for additional flexibility when needed - especially for larger woodworking projects where I can take advantage of "pipe making muscle memory".