Some words as introduction: I often see stems with convex or concave curves from sattle to bit. I think, and Rainer Barbi told me too, that is the wrong way! It needs a lot of time and often doesn't look very well. Take Dunhill as example: They do all their stems straight!

So, if anyone's interested:

1st I cut a peace of ebonit from a rod. The length should be as long as the seeable part should be plus 15 mm for the tennon.

The tennon should be done with a lathe or any thing else. For pipes without filter I prefer 7 mm diameter. I think I don't have to say anything about that...

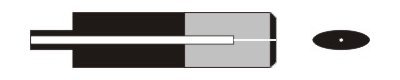

Then I drill the 1st airhole 15 mm deep from the bit side, the 2nd with 3.0 or 3.5 mm from the tennon side as long as needed to keep the first drill.

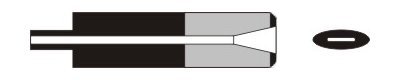

The next step is to flatten the upper and under sides. I do this at first with a sanding disc with 24 grid (the same I use for my rough bowl). At the bit side a minimum of 7 mm must be remaining for the bars of the bit!

sideview:

Then I take a flt file with one even side and one side with ripples. With the rippled side I mark the length of the bars at both sides. I file as far as the bar's length should be:

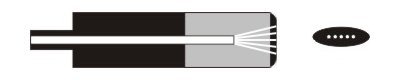

view from above:

Then I file a straight line from edge to edge to get the bars. The sides of the bars are filed with 45° over the length of the bars. And after that I file (the even side of the file directed to the bars of the bit) from the bit to the sattle a straight line:

view from above:

sideview:

The bars of the bit are rounded oval from side to side and the aerea of the upper and under side are rounded fron the middle of the stem to the sides with the file.

Now let's have a look to the airway of the bit:

To get a whide airflow to dispense the smoke, I work a "V" into the bit side. I drill 5 holes with 1.5 mm from the faceside of the stem to the port of the 3 or 3.5 mm airway:

After that I use the 1.5 mm drillbit to cut away the material between the holes. The "V" must be flattened with a nailfile to remove any ridges inside the bit.

After that I mount the stem to the pipe and do the stem/shank junction with abressive cloth - in future with a sanding belt, I hope...

That's it! Easy to do and looking very nice...