Note: Loose Chuck = Oh ......

-

ZeroContent

- Posts: 8

- Joined: Sat Dec 11, 2010 6:33 pm

Note: Loose Chuck = Oh ......

Yea. So I was drilling the airway in a piece of briar on my lathe. Had about 4 inches drilled when all hell broke loose. My drillbit chuck came loose from the mortis, started spinning, then vibrating then the bit must have buckled then broke then the chuck and briar went flying. Now I'm paranoid the drill chuck will come loose again. I set it really well this time. Hopefully just a freak thing. Hope I can salvage the briar, I'm gonna have to cut a 1/4" off to grab hold of the bit to pull it out.

Good times.

Good times.

Re: Note: Loose Chuck = Oh ......

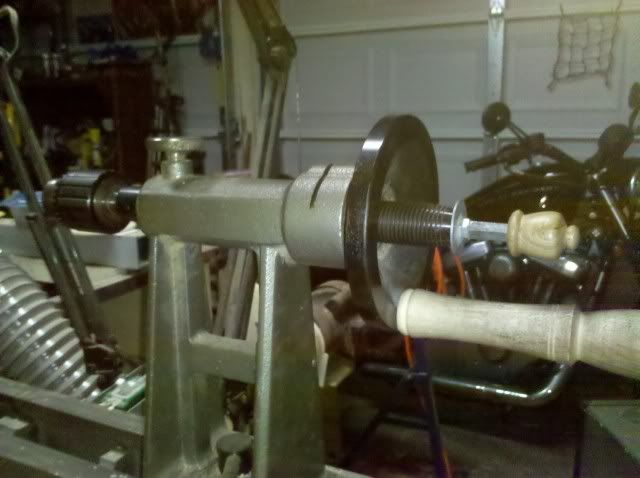

I have a piece of all-thread with a fender washer and a knob on one end that threads into the chuck through the tailstock ram.

Re: Note: Loose Chuck = Oh ......

I did not understand one word of this.Grammaton wrote:I have a piece of all-thread with a fender washer and a knob on one end that threads into the chuck through the tailstock ram.

Rad

Re: Note: Loose Chuck = Oh ......

On most wood lathes you can punch the various mountable tools (chucks, live centers etc) out of their wedged in position with a long rod that fits through either the spindle or the tailstock (the ram being the moving part). What G is saying is that he can lock his chuck into place with a long threaded bolt that goes through the tailstock, threads into the chuck (presumably into the end of the tapered steel segment) and prevents it from loosening by tightening against.... well... what the hell does it tighten against, Gram? It would hit the handcrank on mine.....

I demand a picture!

I demand a picture!

ALL YOUR PIPE ARE BELONG TO US!

Re: Note: Loose Chuck = Oh ......

I did not understand this either. What the hell is a wood lathe?Sasquatch wrote:On most wood lathes you can punch the various mountable tools (chucks, live centers etc) out of their wedged in position with a long rod that fits through either the spindle or the tailstock (the ram being the moving part). What G is saying is that he can lock his chuck into place with a long threaded bolt that goes through the tailstock, threads into the chuck (presumably into the end of the tapered steel segment) and prevents it from loosening by tightening against.... well... what the hell does it tighten against, Gram? It would hit the handcrank on mine.....

I demand a picture!

Rad

- Tyler

- Site Supporter

- Posts: 2376

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: Farmersville, TX

- Contact:

Re: Note: Loose Chuck = Oh ......

It's an awkward tool that'll do, if'n you don't have the coin for a "real" lathe. Come over to my place sometime, and I'll show you how to use one. I can even show you how to quit making doorstops like you're making with that good lathe of yours now.RadDavis wrote:I did not understand this either. What the hell is a wood lathe?Sasquatch wrote:On most wood lathes you can punch the various mountable tools (chucks, live centers etc) out of their wedged in position with a long rod that fits through either the spindle or the tailstock (the ram being the moving part). What G is saying is that he can lock his chuck into place with a long threaded bolt that goes through the tailstock, threads into the chuck (presumably into the end of the tapered steel segment) and prevents it from loosening by tightening against.... well... what the hell does it tighten against, Gram? It would hit the handcrank on mine.....

I demand a picture!

Rad

Tyler Lane Pipes

http://www.tylerlanepipes.com

http://www.tylerlanepipes.com

Re: Note: Loose Chuck = Oh ......

Sorry Rad, Grammaton and I make pipes with skill and daring rather than have some machine do it all fur us.

But that's cool. To each his own.

But that's cool. To each his own.

ALL YOUR PIPE ARE BELONG TO US!

Re: Note: Loose Chuck = Oh ......

I mean to say "I use a drawbar." I don't know why I didn't.

I did have to make a longer handle for the crank.

The cool thing about a wood lathe is I can turn a convex curve then a concave curve then a taper (flat or curved) then a straight flat section, then beads, then grooves, in wood, plastic, aluminum, or brass, without adjusting anything but my elbow.

I don't turn aluminum or brass very often. I turn lots of wood, and a bit of plastic.

The drawback is I have to rely on my skill as a turner to get to finished shape and diameter, rather than dials on the cross-slide and specially ground tools.

The reason for using a drawbar is because if you don't clear chips often enough, they bind and cause the chuck to pop out of the taper when you finally back it out to clear because you hear it bind and maybe see smoke.

I did have to make a longer handle for the crank.

The cool thing about a wood lathe is I can turn a convex curve then a concave curve then a taper (flat or curved) then a straight flat section, then beads, then grooves, in wood, plastic, aluminum, or brass, without adjusting anything but my elbow.

I don't turn aluminum or brass very often. I turn lots of wood, and a bit of plastic.

The drawback is I have to rely on my skill as a turner to get to finished shape and diameter, rather than dials on the cross-slide and specially ground tools.

The reason for using a drawbar is because if you don't clear chips often enough, they bind and cause the chuck to pop out of the taper when you finally back it out to clear because you hear it bind and maybe see smoke.

Re: Note: Loose Chuck = Oh ......

The reason I use a wood lathe is ... I have one. That's reason enough. Most of the guys here use a metal lathe because it offers a few quick-easies that the wood lathe doesn't, but allows you to use it as a wood lathe if you like. I like to take shots at these guys simply because my setup is so limited and so mediocre and my pipes are so incredibly great that I must be very, very talented indeed!

I gotta go look at my lathe now and see if I could do that setup or not. I don't drill much on the lathe but it would be good to know.

I gotta go look at my lathe now and see if I could do that setup or not. I don't drill much on the lathe but it would be good to know.

ALL YOUR PIPE ARE BELONG TO US!

-

smokindawg

- Posts: 417

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: Missouri

- Contact:

Re: Note: Loose Chuck = Oh ......

I have and use both a wood lathe and a metal lathe. Mostly because I have too much money....... "Yea Right"

I have both because I started with a wood lathe and it's tooled up good for pipe making and I see no sense in selling off a good useful tool that I still use on occasion and would loose money on, even though I now have the metal lathe that is tooled up better than the wood lathe.

Both have their uses, some jobs of which can be done on either.

I have both because I started with a wood lathe and it's tooled up good for pipe making and I see no sense in selling off a good useful tool that I still use on occasion and would loose money on, even though I now have the metal lathe that is tooled up better than the wood lathe.

Both have their uses, some jobs of which can be done on either.

Pipe Maker in the Making!

Re: Note: Loose Chuck = Oh ......

I was kidding about relying on dials and special tools. Sorry if it read differently.

I'm not saying I don't wish I had a metal lathe, cause I do, but not for making pipes. In a pinch, either one can do most jobs. But both are best suited for their intended purpose.

I'm not saying I don't wish I had a metal lathe, cause I do, but not for making pipes. In a pinch, either one can do most jobs. But both are best suited for their intended purpose.

- SimeonTurner

- Site Supporter

- Posts: 750

- Joined: Wed Dec 24, 2008 7:46 pm

- Location: Denver, Colorado

- Contact:

Re: Note: Loose Chuck = Oh ......

Guys, Rad doesn't use a lathe at all (metal or wood). He just gnaws on the briar cantankerously. You think his sandblasts are nice? Not a sand blaster. He just rubs the pipe on his beard to get that effect.

Rad Davis is pretty much the Chuck Norris of pipe making.

Rad Davis is pretty much the Chuck Norris of pipe making.

"It is noble to be good; it is still nobler to teach others to be good - and less trouble."

Turner Pipes Website:

http://www.turnerpipes.com

Of Briar and Ashes:

http://turnerpipes.wordpress.com

Turner Pipes Website:

http://www.turnerpipes.com

Of Briar and Ashes:

http://turnerpipes.wordpress.com

Re: Note: Loose Chuck = Oh ......

Pictures or video please?SimeonTurner wrote:Guys, Rad doesn't use a lathe at all (metal or wood). He just gnaws on the briar cantankerously. You think his sandblasts are nice? Not a sand blaster. He just rubs the pipe on his beard to get that effect.

Kola

- SimeonTurner

- Site Supporter

- Posts: 750

- Joined: Wed Dec 24, 2008 7:46 pm

- Location: Denver, Colorado

- Contact:

Re: Note: Loose Chuck = Oh ......

I might get arrested on obcenity/indecency charges if I post videos of Rad.

"It is noble to be good; it is still nobler to teach others to be good - and less trouble."

Turner Pipes Website:

http://www.turnerpipes.com

Of Briar and Ashes:

http://turnerpipes.wordpress.com

Turner Pipes Website:

http://www.turnerpipes.com

Of Briar and Ashes:

http://turnerpipes.wordpress.com

Re: Note: Loose Chuck = Oh ......

SimeonTurner wrote:I might get arrested on obcenity/indecency charges if I post videos of Rad.

Yeah, I heard Rad makes pipes in the nude and we don't need to see that.