2 Stem Questions.

2 Stem Questions.

1. How you do you mount a stem in a wood lathe to keep it completely centered? I saw Todd Bannard's way of doing it, I'm just wondering if anyone has any alternatives?

2. How do I cut the stem? The stem being either acrylic or vulcanite. Can I cut it with a parting tool while in my lathe? Can I cut it with my coping saw while in my lathe? Both of these methods sound like it would create too much heat due to the friction but I've not tried it yet.

I just got two 18" pieces of vulcanite stock and I plan on playing around with them this weekend but I would like some guidance so I don't end up wasting all of it.

Thank ya much,

Dave

2. How do I cut the stem? The stem being either acrylic or vulcanite. Can I cut it with a parting tool while in my lathe? Can I cut it with my coping saw while in my lathe? Both of these methods sound like it would create too much heat due to the friction but I've not tried it yet.

I just got two 18" pieces of vulcanite stock and I plan on playing around with them this weekend but I would like some guidance so I don't end up wasting all of it.

Thank ya much,

Dave

Go hang a salami I'm a lasagna hog.

Re: 2 Stem Questions.

Let me tell you one thing: Todd Bannard is full of shit, and he's dumber than a stoned tow-truck driver.

SHARP tools will cut both vulcanite and acrylic. Both will heat up a bit. Usually not an issue with vulcanite, but acrylic you need to keep cool. I use a little squirt bottle (an oiler) full of soapy water for this.

You can't take monstrous amounts of material out because the stuff will chatter and vibrate etc, but working slow and careful with sharp tools it's all pretty friendly stuff.

Parting tool good. Coping saw bad. If the saw gets pinched it'll kickback and wreck the saw, the workpiece, or a finger.

SHARP tools will cut both vulcanite and acrylic. Both will heat up a bit. Usually not an issue with vulcanite, but acrylic you need to keep cool. I use a little squirt bottle (an oiler) full of soapy water for this.

You can't take monstrous amounts of material out because the stuff will chatter and vibrate etc, but working slow and careful with sharp tools it's all pretty friendly stuff.

Parting tool good. Coping saw bad. If the saw gets pinched it'll kickback and wreck the saw, the workpiece, or a finger.

ALL YOUR PIPE ARE BELONG TO US!

Re: 2 Stem Questions.

He IS a stoned tow-truck driver, isn't he? Last I heard, anyways....Sasquatch wrote:Let me tell you one thing: Todd Bannard is full of shit, and he's dumber than a stoned tow-truck driver.

Re: 2 Stem Questions.

Hey Todd! We meet again. So dude, even though you are a piece of shit (J/K), I still have questions for you. I got a block of wood drilled to my faceplate, just like your stet up. Since there are pretty much no alternatives to your method, can you explain in detail how this piece of wood holds the stem in place without it rotating? I tried drilling a slight hole with a forstner bit but obviously that didn't work. I'm working with both acrylic and vulcanite and both come in different diameters, in fact the acrylic isn't even a circumference, it's closer to being square. I just need something too keep it level so there is minimal wobble and a way to check the tenon every five seconds to check for size.

Thanks Sasquatch!

Thanks Sasquatch!

Go hang a salami I'm a lasagna hog.

Re: 2 Stem Questions.

Ooooops, sorry I meant full of shit not a "piece of shit." Just needed to clear that up.

Go hang a salami I'm a lasagna hog.

Re: 2 Stem Questions.

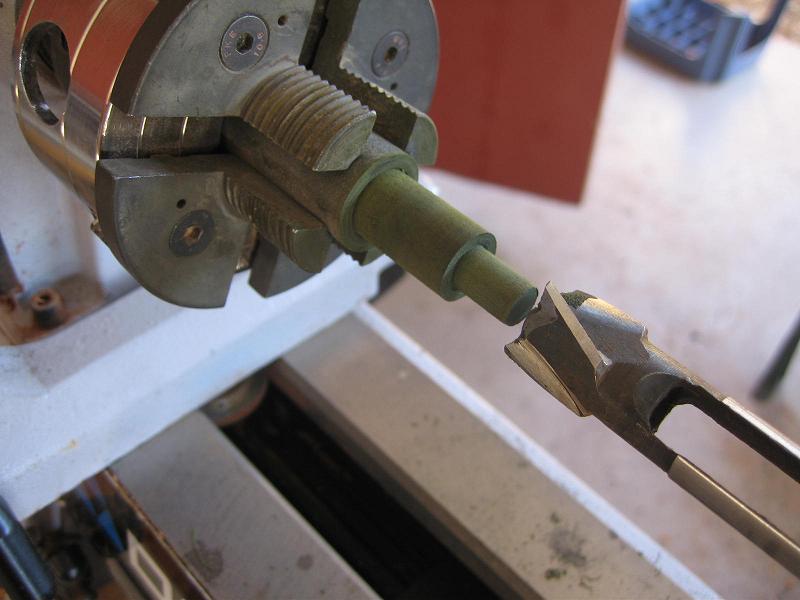

I cut or carve a slot in the wood plate which accepts the fistail of the stem. To center this, turn on the lathe with the plate mounted and run a pencil on the plate and make a series of concentric circles like a bullseye. Then cut a button-sized slot in the middle of that. Mine is about 3/16" high, 3/4" wide, and about 1/8" deep. Can be cut with anything from carving gouges to a knife to a sliding miter saw.

So I grind the rod into a rough fishtail and insert it. You can see that here.

So I grind the rod into a rough fishtail and insert it. You can see that here.

Last edited by Sasquatch on Sat Mar 12, 2011 11:59 pm, edited 1 time in total.

ALL YOUR PIPE ARE BELONG TO US!

Re: 2 Stem Questions.

You can also rig up your chuck to accept a stem - people insert a screwdriver tip and into the chuck and fit that to the slot of the stem. Or if you are using rod stock you can put it right in the chuck too. There's always ways.

ALL YOUR PIPE ARE BELONG TO US!

Re: 2 Stem Questions.

Okay, I lied, 3 questions. Here is the 3rd: What size bit is standard when drilling the stem? Do you use a smaller bit at the end where the button is? Or, do you use the same size though out? I was using a dremel tool to do the slit but it seems all the saw bits are too wide and it cuts a slit all the way across the width. Any suggestions?

Go hang a salami I'm a lasagna hog.

Re: 2 Stem Questions.

There's about a hundred ways to do it. I use a smaller bit at the button - 1/16" or so. The hole coming from the tenon tapers down, and I connect up to this with a 1/16" bit (or you can get a real long 1/16" bit and drill it from the same side.

The you have to widen out the hole to make a slot. I drill a 1/2" deep hole on either side of my original hole and then file/saw all the crap out.

X-acto has a great blade for this process - http://www.xacto.com/Product/X215

As for airway size, there isn't one right standard. Anything from 1/8" to 11/64 works fine as far as I can tell. 5/32 is probably "standard".

The you have to widen out the hole to make a slot. I drill a 1/2" deep hole on either side of my original hole and then file/saw all the crap out.

X-acto has a great blade for this process - http://www.xacto.com/Product/X215

As for airway size, there isn't one right standard. Anything from 1/8" to 11/64 works fine as far as I can tell. 5/32 is probably "standard".

ALL YOUR PIPE ARE BELONG TO US!

Re: 2 Stem Questions.

Here's the Dremel tool that a lot of makers use for the slot:

http://www.amazon.com/Dremel-199-High-S ... B00004UDGP

Rad

http://www.amazon.com/Dremel-199-High-S ... B00004UDGP

Rad

Re: 2 Stem Questions.

Seems to me, it can be done a lot easier if you are using rod stock -

Disclaimer:

This is coming from a rookie pipe maker with limited tooling. You learn to use what you have to do the job you need. I have a wood lathe only, but I did save up and buy a couple of chucks.

Use a chuck that will accept the rod stock (or change the jaws). The chuck on the left has the #1 spigot jaws (One Way)

I use a (wood) tenon cutter set (sometimes) to rough the rod closer to final diameter. I will also use a little smaller one to rough out the tenon.

I will finish the tenon on a tenon cutter (from Pipe Makers Emporium). There are times I will face the end of the rod and drill to accept a piece of delrin rod.

If you wanted a fancy button by the tenon, just use the lathe chisels here to do your shaping. Kurt recently posed some great videos doing this.

Then I would drill the airway using a tapered drill bit - ending about an inch short of the bit end.

Flip the rod around, cut the rest of the OD down to size and drill the rest of the air hole (I use 1/16").

Now days I use a long 1/16" bit that I use from the tenon side when I drill the airway.

I use the saw cutter Rad posted to start the slot then use a 1/16" drill bit in a dremel to cut the V slot using side pressure (smearing) the slot.

Disclaimer:

This is coming from a rookie pipe maker with limited tooling. You learn to use what you have to do the job you need. I have a wood lathe only, but I did save up and buy a couple of chucks.

Use a chuck that will accept the rod stock (or change the jaws). The chuck on the left has the #1 spigot jaws (One Way)

I use a (wood) tenon cutter set (sometimes) to rough the rod closer to final diameter. I will also use a little smaller one to rough out the tenon.

I will finish the tenon on a tenon cutter (from Pipe Makers Emporium). There are times I will face the end of the rod and drill to accept a piece of delrin rod.

If you wanted a fancy button by the tenon, just use the lathe chisels here to do your shaping. Kurt recently posed some great videos doing this.

Then I would drill the airway using a tapered drill bit - ending about an inch short of the bit end.

Flip the rod around, cut the rest of the OD down to size and drill the rest of the air hole (I use 1/16").

Now days I use a long 1/16" bit that I use from the tenon side when I drill the airway.

I use the saw cutter Rad posted to start the slot then use a 1/16" drill bit in a dremel to cut the V slot using side pressure (smearing) the slot.

Kim Kendall

http://www.PenguinBriar.com/

http://www.PenguinBriar.com/

-

bloodysafety

- Posts: 19

- Joined: Mon Feb 28, 2011 9:35 am

Re: 2 Stem Questions.

i gust remove the center from the headstock and the point from the tail stock, round over the ends to make a slight cone and mount it like that. i just crank down the tailstock every once and awhile. I know there are better ways but it works for me. untill i get a fancy chuck anyway!