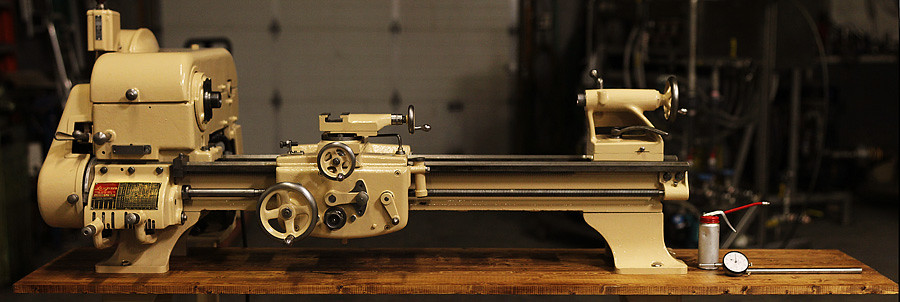

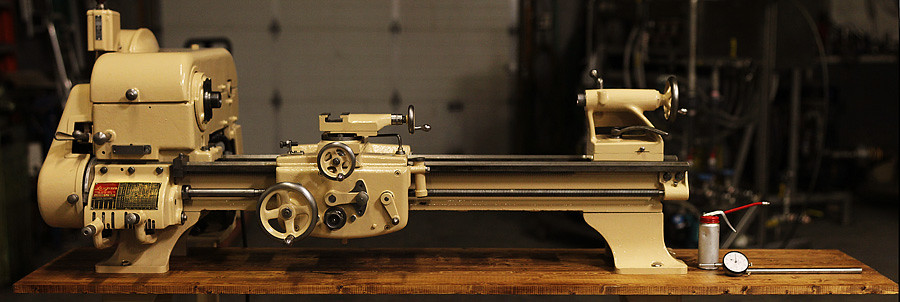

The colour scheme was inspired by the planet Tatooine from Star Wars, because I'm a huge nerd.

Unfortunately I forgot to take before photos... I think I was just too excited to get started on it, haha.The Smoking Yeti wrote:That's puuuurty! Can you do some before n after comparisons?

Thanks! The cranks I just used some abrasive pads and a powered rotary wire brush. I liked the satin finish, it's a bit different than the mirror finish some machines have on the cranks. The ways were in really good shape when I bought the machine, so I didn't tamper with them much, just removed some very minor surface rust and re-lubed them.Zeppo- wrote:Very beautiful, it's a pleasure to see one cleaned up like that, It looks better then new. I have the same lathe in considerably rougher condition. How did you get the ways, cranks etc. so clean?

-Palmer