Page 1 of 1

Making a Military-Style Stem from a Molded Blank (video set)

Posted: Wed Aug 22, 2018 1:41 am

by LatakiaLover

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Wed Aug 22, 2018 3:27 am

by caskwith

I can't comment on the video but you mention in Video 1 that it is difficult to chuck up pre-form stems in a lathe, you know what my response to that will be

lol

Does that make me a "lathe guru"?

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Wed Aug 22, 2018 10:02 am

by scotties22

caskwith wrote:I can't comment on the video but you mention in Video 1 that it is difficult to chuck up pre-form stems in a lathe, you know what my response to that will be

lol

Does that make me a "lathe guru"?

Not to derail the thread, but I want to talk to you about how you do that accurately and safely. We just bought Heath one of Tim West's tenon cutters for his Crappy Pipes and I'd rather learn from someone else's mistakes than make my own. I have an extra chuck that I can modify or make jaws for if that's what you've done.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Wed Aug 22, 2018 10:49 am

by sandahlpipe

I haven't made a military mount pre-form on the lathe, but I've turned tenons by chucking them on pin gauges after opening the airways. You have to have your tools sharp or the pressure will push the stem off the pin gauge.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Wed Aug 22, 2018 10:55 am

by scotties22

sandahlpipe wrote:I haven't made a military mount pre-form on the lathe, but I've turned tenons by chucking them on pin gauges after opening the airways. You have to have your tools sharp or the pressure will push the stem off the pin gauge.

I've done that as well. I'm looking for how to chuck it as the tenon cutter will be in the tailstock.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Wed Aug 22, 2018 1:22 pm

by LatakiaLover

caskwith wrote:I can't comment on the video but you mention in Video 1 that it is difficult to chuck up pre-form stems in a lathe, you know what my response to that will be

lol

Does that make me a "lathe guru"?

I've messed with it some, and finally decided that in theory ANY object (that will fit, of course) can be grabbed by a 4-jaw chuck and centered with a dial indicator. The challenge being how long it takes, and, when applicable, not marring the surface of the clamped object (such as in this case).

If you still have your video camera---I'm sure you still have your uber-cool Little Red Myford

---I'd love to actually see how you'd do it. Trying to imagine having only the blade portion of a molded blank to grab and still have cutting access to the 50% protruding from the chuck makes my brain hurt.

Maybe my little Atlas will get more use afterward.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Wed Aug 22, 2018 4:07 pm

by caskwith

I'll dig out a preform and take some pictures to illustrate.

For now though you can ponder on this. 4 basic ways to do it off the top of my head:

1. 4 Jaw chuck, very accurate, will work on most circumstances, very slow, I almost never do it.

2. Custom lathe jaws, pretty accurate, super fast, pricey.

3. Custom shaped "pin" in the headstock and live centre, very fast, pretty accurate, might need several pins to cover a range of stems and very gentle cuts only!

3. Collet chuck and live centre, fast, super accurate, very versatile, very pricey. This is the system I use as I have a complete collet chuck system for my lathe. It works a charm and I can do just about anything to a premolded stem. I only need a couple of mm to grip in the collect, the live centre holds it steady for working. Depending on the stem you may need to take light cuts but that's not a problem.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Wed Aug 22, 2018 4:28 pm

by seamonster

.....just as long as everyone is #emotionally_satisfied.

Thank you George!

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Wed Aug 22, 2018 4:55 pm

by caskwith

scotties22 wrote:sandahlpipe wrote:I haven't made a military mount pre-form on the lathe, but I've turned tenons by chucking them on pin gauges after opening the airways. You have to have your tools sharp or the pressure will push the stem off the pin gauge.

I've done that as well. I'm looking for how to chuck it as the tenon cutter will be in the tailstock.

If you want to use a tenon cutter then you are best off going down the custom jaw route as it will allow you a firmer grip of the stem near the end where you are cutting the tenon. If you are turning tenons in the traditional manner then my collet chuck/live centre method is ideal.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Wed Aug 22, 2018 6:07 pm

by scotties22

caskwith wrote:scotties22 wrote:sandahlpipe wrote:I haven't made a military mount pre-form on the lathe, but I've turned tenons by chucking them on pin gauges after opening the airways. You have to have your tools sharp or the pressure will push the stem off the pin gauge.

I've done that as well. I'm looking for how to chuck it as the tenon cutter will be in the tailstock.

If you want to use a tenon cutter then you are best off going down the custom jaw route as it will allow you a firmer grip of the stem near the end where you are cutting the tenon. If you are turning tenons in the traditional manner then my collet chuck/live centre method is ideal.

Kinda what I thought. Thanks

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Wed Aug 22, 2018 6:13 pm

by LatakiaLover

caskwith wrote:

1. 4 Jaw chuck, very accurate, will work on most circumstances, very slow, I almost never do it.

OK, now I feel less crazy.

I can imagine a collet set that would work (but damn you'd have to have a shit-ton of them), though the "live center" business I'll still have to see pics of to understand.

In functional terms, though, the "lathe solution" is a molded-stem-grabber of some sort which in TURN gets mounted into a lathe chuck. (It would even be possible to build a spinnable---meaning balanced---version of my drill press's

xy table w/"loose plate" widget on it, and attach a chuckable mounting post to the bottom, I suppose.)

That, as the man said, changes everything. I was being too literal. A "middleman" clamping mechanism that can be chucked isn't mysterious...

I'm eager to see any photos you might post, CA. I'm sure what you are doing is more elegant than my imaginator can imaginate.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Thu Aug 23, 2018 2:17 am

by caskwith

Trent Rudat makes a set of V jaws designed for holding stems, basically a spinning version of the V jaws that factories use to clamp their stems. Scottie this is likely the best solution for your problem with the tenon cutter.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Thu Aug 23, 2018 9:01 am

by scotties22

That's kinda what I was thinking too. I've been devising a way to modify my extra pen jaws with some wood chunks with v grooves cut into them. It'll either work or be an epic failure, lol

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Thu Aug 23, 2018 9:35 am

by caskwith

As long as you use a close grained hardwood (like briar) you should be fine doing that. The jaws won't last as long as metal of course but if you are not doing thousands of stems a year I am sure they will last plenty long. I have made custom wooden inserts for lathe jobs before and they hold up just fine, heck I have turned items only held to the lathe with hot glue and a strong fart and it's worked.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Thu Aug 23, 2018 9:46 am

by caskwith

Ok some pictures as promised. First for George is a picture of my collet set, they cover the range of 3mm - 30mm, that's a complete set for ER40 collets. An ER32 set is much cheaper and probably covers all the sizes a pipe maker would need but I got a great deal on the ER40 and I am surprised how often I use the larger collets (not pipe work usually).

Then a couple of pictures of the stem gripped by the button and supported with a live centre. For demonstration purposes I have just put the button directly in the collet, which is fine in most cases but if you have a delicate button or just want to more careful you could certainly put on a couple of turns of tape as you showed in your video and I have done this myself many times, I just use plain electrical tape though.

This stem is in there good and solid, the button will not slip and you could turn a tenon with no trouble at all or entirely re-shape the stem you just need to take light cuts at a high RPM to avoid chatter as the stem itself will flex.

Finally I did shoot a few seconds of video just to demonstrate that even this totally raw moulded vulcanite pre-form is running perfectly true.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Thu Aug 23, 2018 2:34 pm

by LatakiaLover

Muchacho gracioso, Chris.

I had "moveable axis" in mind when you said "live center"

but the reality is much simpler. Me gets it now.

My only question is whether setting things up as shown is how your LatheBrain would approach the problem if asked to solve it, or if it truly works in practice.

What gives me pause (since I work with molded stems a lot) is how frequently their airway is off axis, meaning cutting contact would be intermittent until a certain depth was achieved. And the chatter, recoil, etc. of the blade portion twisting DURING the contact period would be fierce. Also, how often does the button slip/spin in the collet, given that the contact area is so small?

Replacing the collet set with a chuckable cylinder with a cone cut into one end---and a v-shaped slot cut into THAT---would solve any slippage problem, but wouldn't help with the twist/flex one.

You say light enough cuts would make that entire category of concern a non-issue, which is literally true, but a hundred passes wouldn't be practical time-wise (not to mention insanity inducing

)

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Thu Aug 23, 2018 3:08 pm

by caskwith

Airway usually is a little off axis but because this method uses the airway for reference, when you turn a tenon you turn one that is perfectly in line with the airway.

As to the button slipping, if you set it up correctly (easy with experience) it never slips and I have never broken a stem using this method. When I say light cuts I guess it's a relative term, for me a light cut is really something less than 0.5mm, I'd be taking passes of somewhere between 0.1 to 0.3mm which is removing a good amount of material at a time. Your feed rate needs to be gentle which you learn by feel and you need a sharp tool which is no problem. Lathe speed needs to be 1000rpm + for a smooth cut.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Thu Aug 23, 2018 3:40 pm

by LatakiaLover

10-4 on all that. Thanks.

If you have a way to mill slots, you should make and sell the conical widget I mentioned. An inch in diameter and a couple inches long ought to be large enough. Material doesn't matter---aluminum, nylon, whatever. The cone cut into one end 45 degrees, the centered V-slot cut into that 3/16" or so tall. Just chuck it quickly in a 3-jaw, insert a stem button-end first, and slide the live-center thingy up tight enough to "trap" it. No muss, no fuss, one-size-fits-all. Such a device would appeal to anyone who had no other need for a collet $et, I imagine, and would be faster in use, too.

Betcha Scottie would be your first customer.

.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Thu Aug 23, 2018 7:29 pm

by scotties22

caskwith wrote:I have turned items only held to the lathe with hot glue and a strong fart and it's worked.

I just used hot glue today to hold a ring on a jamb chuck made from a maple dowel.

Re: Making a Military-Style Stem from a Molded Blank (video

Posted: Sun Aug 26, 2018 4:06 pm

by DocAitch

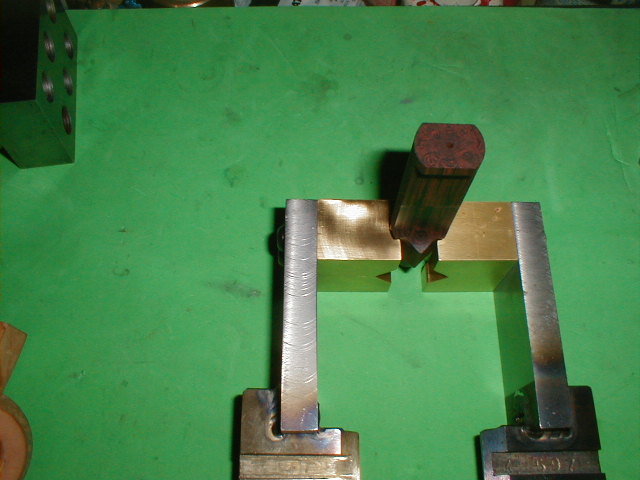

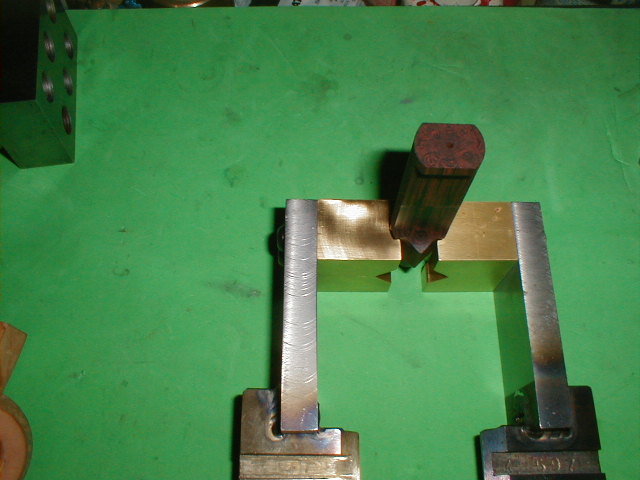

This is the set up that I used with molded stems. It does require a smaller cut, and both the stem and the holder must be indexed to give a concentric cut if the bit gets taken out of the set up for a trial fit. The button centers itself on the 4 corners. The corners will mark the button, but not badly (deeply).

There is another method using a screw driver blade, but the bit material is placed more in tension for the most part (while this method places the bulk of the material in compression) and I suspect the stem blade will shatter more easily.

I cut the V slot with a file, milling would be better but this works fine.

Break the corners where the V and the 7/16” hole meet to reduce the marking/cutting by the corners.

I occasionally still use this to do touch up work on my rod cut stems.

You also have to grind the cutting bit to fit between the tenon and the center to cut a 1/4” or 5/16” tenon.

The wooden prototype is from a piece of tool handle. It works fine but would wear out with any kind of volume production like that of Crappy Pipes. 1” Delrin might work very well.

lol

lol