With freehands, you tend to have to figure out what you're doing as you go along, allowing the wood to dictate much of what you're doing and how you're doing it.

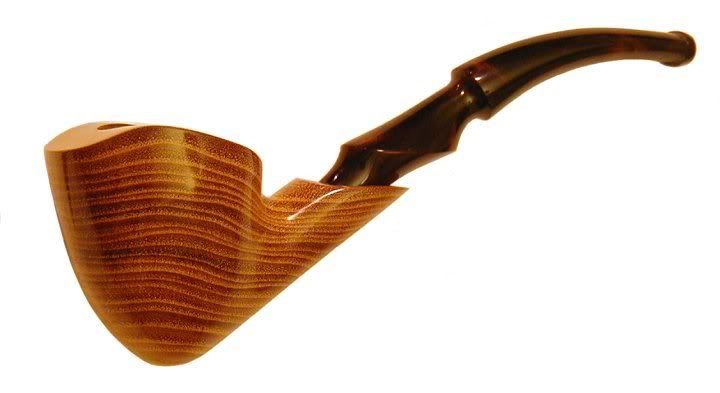

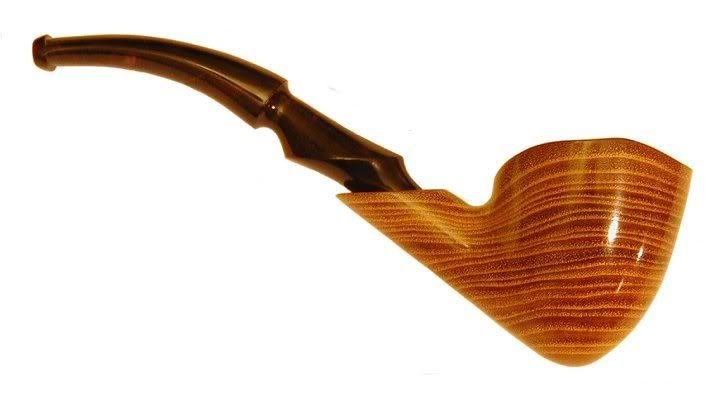

But take this pipe: I've made two different stems for it, and I'm still not very happy about the transition from the shank to the stem. So I'm currently debating about making a third, but I think I'll wait and kinda "sleep on it" for a few days.

Anywho, the story on this pipe is that I made another very similar to this one awhile back, and it's become a regular in my rotation. As near as I can tell, I've probably put around a hundred bowls of tobacco through it, and it's really turned out to be a nice smoker.

So a friend of mine saw me smoking that pipe one day and decided he had to have one just like it. His pipe is what you see pictured below.

By far the nicest thing about my own personal Osage pipe is the fact that I can smoke 10 very different tobaccos in it over the course of a few days, and no matter what tobacco I'm smoking, I can't taste even a hint of the previous tobacco.

So I've pretty much decided that Osage just doesn't absorb flavors the way that briar does. This may be due to the fact that Osage is a relatively resinous wood -- which sounds bad, but it's really more of a sugary resin, rather than the kind that you might find in, like, pine, for instance.

Osage is essentially a fruit tree -- a cousin to mulberry and fig -- and the seeds of the Osage Orange's fruit -- the hedge apple or horse apple -- were a significant source of vitamin C for Native Americans.

During those few weeks a year when berries were available, they could get their "C" that way, but through the rest of the year, they regularly ate the seeds of the hedge apple for that tanginess that their bodies were actually craving.

This was how Native Americans avoided scurvy and other illnesses that plagued sailors and others up until the time when oranges were found to ward off those diseases.

Native Americans carried these seeds, they ate them, and they planted them ... profusely ... which is why Osage Orange now grows throughout much of North America today.

Because not only were the seeds of the Osage Orange a staple in the Native American diet, the wood of the Osage Orange was without a doubt the most highly prized of bow woods.

The French, who were rather friendly with Native Americans for quite some time before other settlers started arriving, called the tree "Bois d'Arc" -- a name still in common use today. Bois d'Arc means "bow wood".

Why I'm going into all of this is because a bow represents perhaps the hardest working piece of wood there is. Bow wood has to withstand tension, compression, splitting, etc. So a wood prized for making bows, above all other woods in North America, is gonna be pretty doggone durable.

That means it will easily withstand the rigors of pipe construction: it will handle a tenon about as tight as any sane pipemaker can throw at it, IOW.

And from my own experience thus far, it seems to resist charring as well as briar does. This isn't based on extensive empirical evidence, mind you, but from what I've seen so far, Osage Orange seems to be pretty much up-to-snuff as a pipe wood.

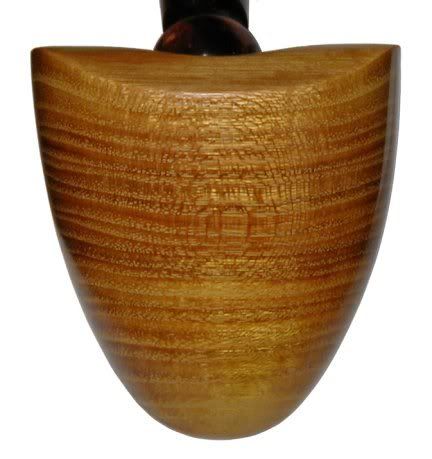

Now then, on the downside, Osage Orange wood does tend to be somewhat ring-porous. About 99 percent of those pores will come out of the tree filled with that sugary resin I mentioned above, but on a pipe this size, you can expect to find at least a few pores that won't easily take a nice, smooth waxing.

So if a handful of visibly empty pores are going to pose a problem, a pipemaker would probably want to go the route of sandblasting.

I tried doing a light coat of shellac on one pipe, but the alcohol in the shellac caused the colors in the Osage to bleed horribly, to the extent that I ended up sanding that particular pipe back down and waxing it.

Polyurethane works well on Osage, except that it tends to be pretty much frowned-on by the pipe smoking/making community.

So waxing-and-accepting-the-occasional-pore or sandblasting-and-waxing seem to be the two best approaches -- that I've come up with thus far, anyway. Somebody else may have a better suggestion, and I'd certainly love to hear it.

And so finally, after all the convoluted rigamarole, I'll post some pictures.

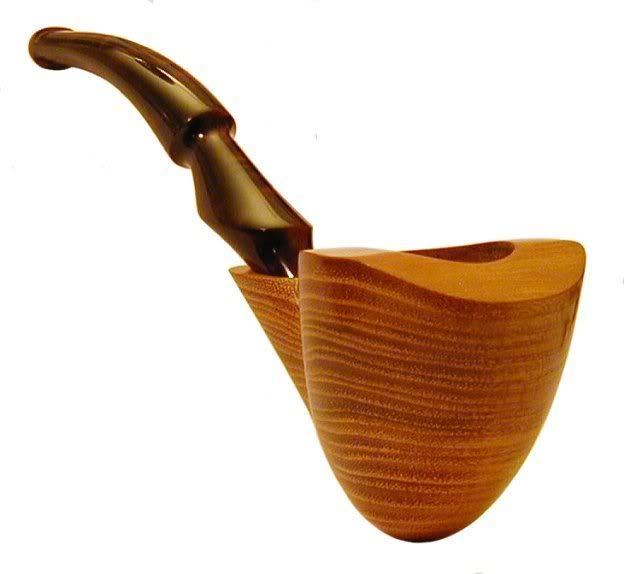

Basically, this stummel is the result of a technique I've been playing around with, whereby I saw out a cross section of a log, split that into sections for more than one pipe, and treat one growth ring of a single section like a "plateaux".

I can't even begin to go into the intricacies of how you work down to the surface of a growth ring -- it's something I learned from my own experience making wood bows similar to those used by the Plains Indians, and involves a combination of whittling and scraping.

But I'm sure you can find out more info about the process if you Google around.

I'm thinking, though, that this process I'm describing of sectioning logs and working down to a single growth ring might have merits for other types of wood -- the point of cross-sectioning being that it's a relatively easy way to harvest logs and convert them into pipes.

And the point of working down to a single growth ring being that it's a nice organic way to add character to a pipe.

Cheers.