Shaping a round shank

Shaping a round shank

Here's a question I've been struggling with: How do you get a round symmetrical shank without the assist of a lathe? I managed to get my last pipe symmetrical but I'm not sure it wasn't more luck than skill. Any suggestions/techniques? I've been contemplating using the PIMO tenon turning tool to get it started. Anyone tried this?

Before I had a lathe

I just took a compass and drew the circle. OMG this is so crude. I cut as much off as possible with a coping saw. Then a rough file to a basic round and switched to a finer file. With the files you have to move them. i.e. start at 6 o'clock with your stroke and end at 12 o'clock, then 3 o'clock to 9 o'clock. The whole point was to move around the shank and NOT file in one spot, let the advancing movement take off the highs and form the round. From there I started with 150 grit??, I think, and cut 1/2 to 1 inch strips. Use it like your were born to shine shoes and move around the shank and move through the grits.

It won't be perfect but it will be damn close. Same with the upper bowl.

Once was enough, and I loosened the purse strings and got a lathe and it was a bygone memory till you brought it up.

It won't be perfect but it will be damn close. Same with the upper bowl.

Once was enough, and I loosened the purse strings and got a lathe and it was a bygone memory till you brought it up.

I generally get my stem as close to final outside diameter as possible on my mini-lathe, then put it into the stummel and trace its diameter around the face with a pencil. Then I cut out what I can and start shaping with either files or the disc sander, depending on how much material I have to work with. When I get my shank close to the tranfered mark, I put the stem back in and work at it with files until I have everything evened up. As CKR mentioned, you have to work your way around the shank and not just keep going at it in one place. After you do it a few times, it gets easier and easier to do without worrying, but a lathe would be a nice birthday present... <sigh>....

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

The first few times you try to make a round thing from a rectangular thing, it's going to be a mix if luck and happenstance that it comes out symmetrical.

I've managed to get pretty close to perfectly round without a lathe, but it's time consuming. My method is similar to the one CKR described, but I use a belt grinder to do the scraping. Basically, you have to rotate the shank as it's in contact with the grinding belt, and use a very light hand. Eventually you develop the skill, and it's no big thing to do. That said, I still prefer to turn it on the lathe as much as I can.

I've managed to get pretty close to perfectly round without a lathe, but it's time consuming. My method is similar to the one CKR described, but I use a belt grinder to do the scraping. Basically, you have to rotate the shank as it's in contact with the grinding belt, and use a very light hand. Eventually you develop the skill, and it's no big thing to do. That said, I still prefer to turn it on the lathe as much as I can.

Not exactly. When I drill the pipe using the lathe, I drill the shank end first (drilling the mortise and air hole first before spinning the block around to drill the tobacco chamber).Michl wrote:When using a lathe, I am assuming that you fasten the

shank end into the headstock to turn it, which means that

you need to have enough stock on the shank end to

be held in a chuck or whatever you are using. You

can;t chuck the stummel end because that would be

too difficult to center. Or?

In this pic below, you can see that the mortise & air hole was drilled and the shank diameter was turned at the same time, so I know that 1) it's round, and 2) it's concentric to the mortise.

If I wanted a longer shank, that's when I would turn it.

Kim Kendall

http://www.PenguinBriar.com/

http://www.PenguinBriar.com/

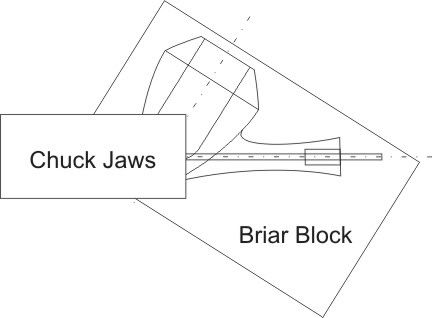

It doesn't matter how bent the shank is in relation to the bowl, as long as the centre line of your mortise is in the centre from chuck to tailstock. That's one of the reasons why many pipemakers have extended jaws on their lathe chucks.Michl wrote:I see how to do this when the shank is straight, but how do you turn a, say, 1/4 bent shank on an author? the shank has to be centered on the lathe, but I can't figure out how you'd attach the briar to the jaw chuck so the shank is centered facing the tail stock.

M

Maybe this illustration will help clarify:

Regards,

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

If you can afford them: http://www.briarpipetooling.com/tooling/Michl wrote:Extended jaws... the missing piece for me. I wonder if I can get some for my chuck.

Regards,

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Interesting. I guess if you had a welder you could machine andFrank wrote:If you can afford them: http://www.briarpipetooling.com/tooling/Michl wrote:Extended jaws... the missing piece for me. I wonder if I can get some for my chuck.

weld them yourself. Would be extravagant for the occasional

pipe I make, but I wonder if this could somehow be improvised by

wedging the briar between two extended pieces between the jaws.

Some folks have made their own extended jaws as you describe. There might be an outside chance of using wedged pieces with 2 self-centreing jaws, but with independant jaws it would be a right bugger keeping everything in place while trying to centre in 3 planes. You also run the risk of the whole kit flying off when you start the lathe. Risky, to say the least.Michl wrote:I guess if you had a welder you could machine and weld them yourself. Would be extravagant for the occasional pipe I make, but I wonder if this could somehow be improvised by wedging the briar between two extended pieces between the jaws.

Regards,

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

The other solution is a nice off-shelf and neatly shrink-wrapped collection of products. And, believe me, coming from me, that's saying something (I do not like shrink-wrapped answers).

Use this chuck:

http://www.pennstateind.com/store/CMG3C.html

With these jaws:

http://www.pennstateind.com/store/LCALJAWS.html

That's a nice solution that doesn't cost an arm and a leg - and works. I use a similar setup, using a OneWay chuck and OneWay Tower jaws that, from about 4 feet away, looks identical to these. These will fit most midi and mini wood lathes on the market today, but check your spindle threads to be sure.

Use this chuck:

http://www.pennstateind.com/store/CMG3C.html

With these jaws:

http://www.pennstateind.com/store/LCALJAWS.html

That's a nice solution that doesn't cost an arm and a leg - and works. I use a similar setup, using a OneWay chuck and OneWay Tower jaws that, from about 4 feet away, looks identical to these. These will fit most midi and mini wood lathes on the market today, but check your spindle threads to be sure.

Earlier I had taken off two jaws and was meditating on the briar wedged between two pieces of wood held by two opposite jaws and came to the same conclusion. There's a reason you want the extensions welded toFrank wrote:but with independant jaws it would be a right bugger keeping everything in place while trying to centre in 3 planes. You also run the risk of the whole kit flying off when you start the lathe. Risky, to say the least.

the jaws.

Thanks for the tip!!! I went and looked at these but have a question about the C jaws. Since they center, they will pull the briar to the center, which will make it hard to center the stummel, since its center is off to one side. With the two extensions you can move the briar up and down the chuck, but it seems that there is very little up and down movement with the centering C jaws. How do you handle that?KurtHuhn wrote: The other solution is a nice off-shelf and neatly shrink-wrapped collection of products. And, believe me, coming from me, that's saying something (I do not like shrink-wrapped answers).

Use this chuck:

http://www.pennstateind.com/store/CMG3C.html

With these jaws:

http://www.pennstateind.com/store/LCALJAWS.html

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

Eh, what now?

I'm not sure I follow you. Yes, these will center any block you put in them so that any hole you drill will be in the center of the block. Very rarely do I want to move the hole from side to side on a block of briar, and when I do want to, I just shave a hair off one side.

If you're having trouble figuring out the subtleties of getting a block of briar drilled and shaped on a lathe, this video may help:

http://blip.tv/file/303461/

I made that a little over two years ago. Grab a drink, it's about 25 minutes long.

I'm not sure I follow you. Yes, these will center any block you put in them so that any hole you drill will be in the center of the block. Very rarely do I want to move the hole from side to side on a block of briar, and when I do want to, I just shave a hair off one side.

If you're having trouble figuring out the subtleties of getting a block of briar drilled and shaped on a lathe, this video may help:

http://blip.tv/file/303461/

I made that a little over two years ago. Grab a drink, it's about 25 minutes long.

Yep. That was my exact question.KurtHuhn wrote:Eh, what now?

Ein, zwei, drei? MEIN GOTT! Das scheiss ear poppin verdammt racketten. Again? Mein kopf ist explodin!KurtHuhn wrote:http://blip.tv/file/303461/

Regards,

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett