Spade bits

Spade bits

I know this has probably been covered a million times, but I need some help. I understand the rounding of the bit, but where I'm stuck at is sharpening it. How do I do it ? Also, I noticed some talk of the bit has a tendancy to walk or chatter, could this be corrected by shortening the shank of the bit.

- ToddJohnson

- Posts: 1366

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: Nashville, TN

- Contact:

As for sharpening, you might find you have the most control with a rotary tool and the bit clamped in a vise. A smooth cylindrical stone grinding tool will put a nice edge on it. You can finish up with a whetstone or diamond hone if you have one. It's a must when you do this day-in and day-out, but some sandpaper on a metal, glass or very flat (MDF, Fiberboard) surface will also do the trick.

Todd

Todd

-

pennsyscot

- Posts: 223

- Joined: Thu Jun 26, 2008 5:03 pm

- Location: pennsylvania USA

- ToddJohnson

- Posts: 1366

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: Nashville, TN

- Contact:

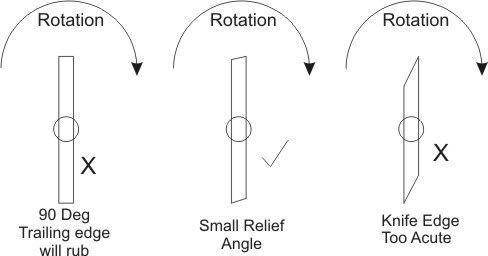

No. You simply relieve the trailing edge. In other words, look at the face of the bit and determine the edge that would actually be doing the cutting when the bit is spinning in a clockwise direction. If you have the bit laying on the table with the shank pointing up, it will be the "right" edge of the face you're looking at. Using that edge as the extreme outside profile of the bit, relieve the back side at about a twenty degree angle. Flip the bit over and do the same thing to the "right" side which, having flipped it over, will be opposite the one you just did. That sounds a little confusing, but just think about relieving the backside of the leading edge, or think about removing material from the trailing edge. All you're trying to do is create a single point of contact, and edge, and remove the material that would create friction.buster wrote:Do you sharpen the side of the bit to look like a knife?

Good luck,

Todd

- SimeonTurner

- Site Supporter

- Posts: 750

- Joined: Wed Dec 24, 2008 7:46 pm

- Location: Denver, Colorado

- Contact:

I picked up a tool at woodcraft that has made sharpeing my lathe tools and my chamber bits much easier. It's totally unnecessary if you have basically good skill with a standard grinder, but since I didn't have skill or confidence when I started pipemaking, I listened to the advice of some of the sales guys at woodcraft who were raving about a tool called the "jooltool".

http://www.jooltool.com/index.htm

I'm not even going to try to explain the tool; I'll let you look at the website and watch the little video to see how it works. Suffice to say, it is really easy to use, and it gives me the ability to sharpen my tools fast and with confidence (mostly because I can see what I'm doing so much better, and the metal doesn't heat up like it does on a grinder, so losing the temper in my lathe tools is less likely).

I usually finish my sharpening with a diamond hone and that's it!

http://www.jooltool.com/index.htm

I'm not even going to try to explain the tool; I'll let you look at the website and watch the little video to see how it works. Suffice to say, it is really easy to use, and it gives me the ability to sharpen my tools fast and with confidence (mostly because I can see what I'm doing so much better, and the metal doesn't heat up like it does on a grinder, so losing the temper in my lathe tools is less likely).

I usually finish my sharpening with a diamond hone and that's it!

- SimeonTurner

- Site Supporter

- Posts: 750

- Joined: Wed Dec 24, 2008 7:46 pm

- Location: Denver, Colorado

- Contact:

Yeah, that's an outrageous price. I bought it at woodcraft for $80 bucks, I believe, plus the cost of a few extra sanding discs (they look like ninja stars).Frank wrote:Interesting gizmo, but $280 seems a bit steep for my pocket.SimeonTurner wrote:...a tool called the "jooltool".

No idea why they would be selling it for so much more online (or maybe why woodcraft was selling it so cheap! LOL)