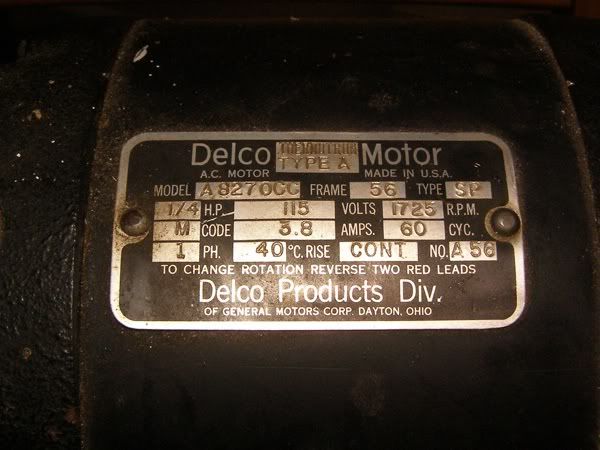

I found something that I had seen many times, but since I never made pipes before it didn't seem very useful to me until now. It's an old 1/4hp motor that he used as a bench grinder (I guarantee because it was cheaper than buying one). I asked my grandmother if anyone ever used the thing and she said I'm welcome to it. I know it's a bit low on power, but it was free

The cool thing is that I found a craftsman keyless chuck with a 5/8" arbor in a drawer, so I can use buffing pads, sanding discs, or whatever you can chuck in a drill. And my wife loves it because it's practically silent. She wasn't too crazy about me buffing pipes inside with a corded hand drill that recommends the use of ear plugs in the instructions

Here are some pics

He even wired in an on/off switch!

I know that most of you go with 1/2hp, so a question I have is will this be able to get the job done?