thank you craigslist

thank you craigslist

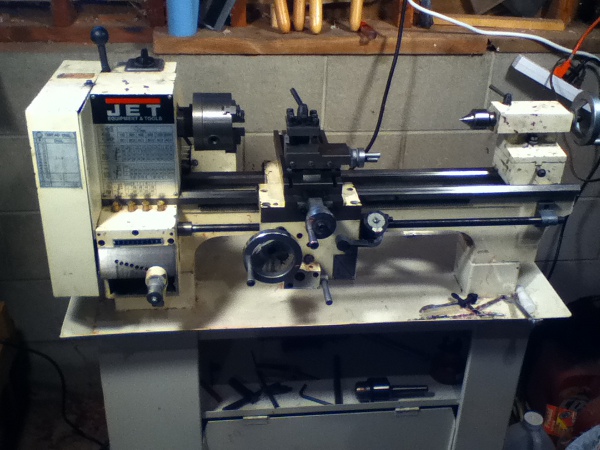

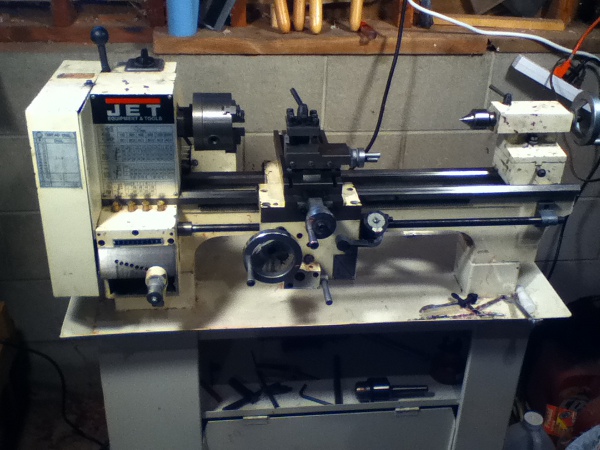

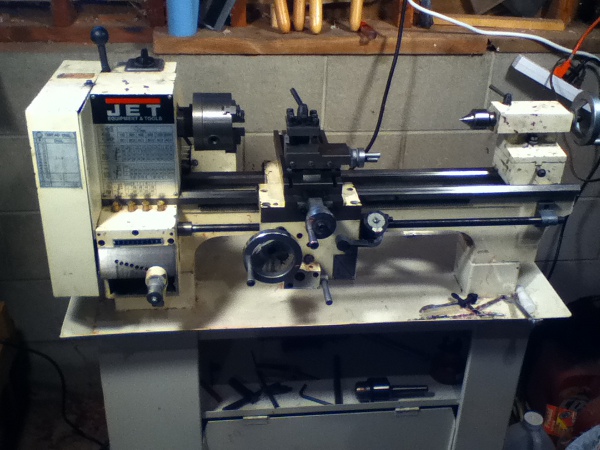

He shoots, he scores! After using one of those 7"x10" hobby lathes for a year, I found a used Jet 9"x20" on craigslist. It reminds me of when I switched from dial-up to cable.

Re: thank you craigslist

Way to go, Eric!

Re: thank you craigslist

Nice score.

Re: thank you craigslist

Congrats Eric! I hope she treats you well. Did you get any good tooling with it?

Re: thank you craigslist

I agree w/the others.. nice find.... someday I'll upgrade my 7x12.. a longer bed is always a nice addition

james

james

Re: thank you craigslist

Thanks guys! I guess now I'll have to start making better pipes.

And, for what it's worth, after having used one for a year, here's my take on getting a 7x10 lathe.

Pros: It is inexpensive. You can cut stem tenons. You can learn metal lathe basics.

Cons: It is flimsy. The key slot on a threading gear wore out after about a week. The speed control quit and I replaced it by soldering on a light dimmer switch from Lowes (don't tell any electrical engineers!). It is too small to drill stummels, so you probably need a drill press too. It is too small for stems longer than about 3". The spindle bore is only about 0.625" so that was the max diameter of my stems.

It came with the usual 3-jaw scrolling and 4-jaw independent chucks. I grabbed a cutter and the live center from the old lathe before selling it to my neighbor. One of these days I'll order a 2 or 4 jaw scrolling chuck and some nice jaws. I've got to do my homework first.Growley wrote:Congrats Eric! I hope she treats you well. Did you get any good tooling with it?

And, for what it's worth, after having used one for a year, here's my take on getting a 7x10 lathe.

Pros: It is inexpensive. You can cut stem tenons. You can learn metal lathe basics.

Cons: It is flimsy. The key slot on a threading gear wore out after about a week. The speed control quit and I replaced it by soldering on a light dimmer switch from Lowes (don't tell any electrical engineers!). It is too small to drill stummels, so you probably need a drill press too. It is too small for stems longer than about 3". The spindle bore is only about 0.625" so that was the max diameter of my stems.

-

smokindawg

- Posts: 417

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: Missouri

- Contact:

Re: thank you craigslist

Eric, congrats on the new lathe. Looks identical to the one I bought a bit over a year ago. Mine came as yours is except it had a nice big QCTP already in place of the factory one. While not necessary, it's nice to have the factory stand as well which is a $350 option when buying a new one.

I then bought a scrolling wood chuck from Grizzly and made my own heavy jaws and that set up is working great. It is nice to have the larger swing I'm sure and the thru hole is large enough for long stem work as well. My buddy has a 6 x 18 and comes over and uses mine on larger or longer stems.

What did you have to pay for it? Did you get the steady rests with it?

I've got links to a couple blogs where guys have shown and explained upgrades to their Jet 9x20's to make them better machines, some easy to do, some a bit more work, but all good upgrades and some I'll be making in the future.

One change I'm going to make for my own safety is too put a removable pin in the directional switch area to keep myself from accidentally turning it on in the wrong direction and this from experience, that chuck can unscrew and drop off in the blink of an eye when turning the wrong direction, especially if the set screw isn't tightened down. I also made a tool rest to install in place of the removeable cross slide so that I could use it for turning like on a wood lathe too.

Also, another thought, one I learned from experience, get at least a couple extra belts for it now (Ebay is a good place) I hated being down for a week because of a broken one.

I then bought a scrolling wood chuck from Grizzly and made my own heavy jaws and that set up is working great. It is nice to have the larger swing I'm sure and the thru hole is large enough for long stem work as well. My buddy has a 6 x 18 and comes over and uses mine on larger or longer stems.

What did you have to pay for it? Did you get the steady rests with it?

I've got links to a couple blogs where guys have shown and explained upgrades to their Jet 9x20's to make them better machines, some easy to do, some a bit more work, but all good upgrades and some I'll be making in the future.

One change I'm going to make for my own safety is too put a removable pin in the directional switch area to keep myself from accidentally turning it on in the wrong direction and this from experience, that chuck can unscrew and drop off in the blink of an eye when turning the wrong direction, especially if the set screw isn't tightened down. I also made a tool rest to install in place of the removeable cross slide so that I could use it for turning like on a wood lathe too.

Also, another thought, one I learned from experience, get at least a couple extra belts for it now (Ebay is a good place) I hated being down for a week because of a broken one.

Pipe Maker in the Making!

Re: thank you craigslist

I found out pretty quickly the consequences of turning the switch to reverse.smokindawg wrote:Eric, congrats on the new lathe. Looks identical to the one I bought a bit over a year ago. Mine came as yours is except it had a nice big QCTP already in place of the factory one. While not necessary, it's nice to have the factory stand as well which is a $350 option when buying a new one.

I then bought a scrolling wood chuck from Grizzly and made my own heavy jaws and that set up is working great. It is nice to have the larger swing I'm sure and the thru hole is large enough for long stem work as well. My buddy has a 6 x 18 and comes over and uses mine on larger or longer stems.

What did you have to pay for it? Did you get the steady rests with it?

I've got links to a couple blogs where guys have shown and explained upgrades to their Jet 9x20's to make them better machines, some easy to do, some a bit more work, but all good upgrades and some I'll be making in the future.

One change I'm going to make for my own safety is too put a removable pin in the directional switch area to keep myself from accidentally turning it on in the wrong direction and this from experience, that chuck can unscrew and drop off in the blink of an eye when turning the wrong direction, especially if the set screw isn't tightened down. I also made a tool rest to install in place of the removeable cross slide so that I could use it for turning like on a wood lathe too.

Also, another thought, one I learned from experience, get at least a couple extra belts for it now (Ebay is a good place) I hated being down for a week because of a broken one.

I had been considering the Grizzly chuck. Did you get the 5" or 6"?

The steady rests were included. I hope I didn't get too ripped off by paying $900. Considering I didn't have to pay shipping, and that it came with the stand and a helpful seller and seems to work fine, I was comfortable with the price. I was about to pull the trigger on a new one which would have been a lot more than that.

It has been fun learning to use the thing. In some ways I feel like I'm starting over, it is so different from the 7x10.