My first bit was just rounded on the end, as it was for a poker shape and a conical bit wasn't needed. But now I'm getting into some different shapes (Bulldog) and I'm going to need a conical bit to get the needed wall thickness.

I know some use a computer drawing program to make templates, but you'd still need to know what shape you want to be able to do that.

So I guess what I'm looking for is what the basic I should be shooting for looks like and if what I've come up with will work. Though I'd like to see how what some other bits look like too.

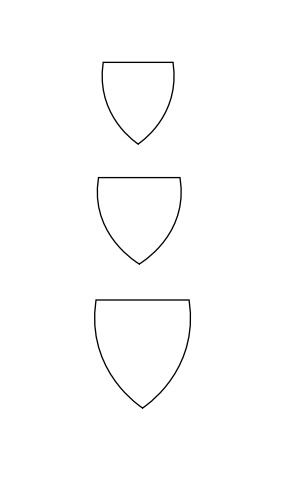

How I've been making my templates is on "Serif DrawPlus", as there is a "badge" template in that program that seems to look like what I would want, so I just went with it. There is a picture of the type of template it makes, though I can stretch them out, make them shorter, wider, basically whatever I want (within reason). Is this OK? Or should I be doing something differently?