Page 1 of 1

Stupid lathe question #3 What the chuck!?

Posted: Fri Oct 19, 2012 10:05 pm

by Ocelot55

So I finally got off the semi fossilized chuck off today so I could measure my spindle. Aside from a mountain of metal, plastic shavings, and sludge that came off with the chuck, I was slightly disappointed with what I discovered.

My spindle is 2"x 8 tpi. The largest adapter made by the Oneway folks is 1 1/2". What's my next option? Theoretically I can attach the chuck to the faceplate, right? How do I know if it will fit? Are there any standards to faceplates? What are my options here?

On a side note, I started dismantling the compound to clean it and found some fierce looking buildup. Is a wire brush something I should use to remove that or would I damage something?

Also is there anything in particular I should use to lightly lubricate the bed and the lead screw? Silicon? WD-40?

What the chuck, man. What the chuck...

Re: Stupid lathe question #3 What the chuck!?

Posted: Sat Oct 20, 2012 12:19 am

by andrew

The first cleaning on an old lathe is always fun

alright, so just a quick check...

Is your spindle 2" or 2-1/4"? Are you measuring from the top of thread to top of thread?

You probably will be into a face plate. Not super expensive. You're in luck, you already have a lathe so you can trim it for your chuck! You'll just need a plain back chuck if you want another chuck. So what kind of chuck came on it?

Re: Stupid lathe question #3 What the chuck!?

Posted: Sat Oct 20, 2012 1:19 am

by Ocelot55

From the top of thread to top of thread it actually measured 1 15/16", granted, my calipers are not the best, no dial. A three jaw chuck came with it fastened on a back plate of the same diameter held on by three screws.

Re: Stupid lathe question #3 What the chuck!?

Posted: Sat Oct 20, 2012 4:08 am

by caskwith

Since you have a metal lathe, and a nice looking one at that, you could make your own thread adaptor. You have 2 choices really, either a collar/stub that screws onto your current spindle nose and has a smaller suiatable thread on the other end, or (the option I would probably chose) get a blank end arbor of the same taper size as your headstock and cut the thread on that. Making either of these in situ on your lathe would provide a very accurate fitment for your chuck.

Re: Stupid lathe question #3 What the chuck!?

Posted: Sat Oct 20, 2012 11:34 am

by d.huber

Did your chuck come off easily? My 3 jaw is stuck on like a beast.

Re: Stupid lathe question #3 What the chuck!?

Posted: Sat Oct 20, 2012 12:29 pm

by wdteipen

How about a chuck with an adapter that simply chucks up in your existing chuck?

Re: Stupid lathe question #3 What the chuck!?

Posted: Sat Oct 20, 2012 1:17 pm

by Ocelot55

@ Chris: I have no clue really how to operate the more complex aspects of the lathe at this point. I think your suggestions, while completely logical and excellent solutions, are like asking a first grader (me) to paint the Mona Lisa.

@ UberHuberManBroDude: Yeah, it came off easily enough when I started turning it the right direction.

@Wayne: I have no clue what you mean. Are you saying mount the chuck onto the back plate, or mount a chuck in a chuck...seems a bit excessive.

Re: Stupid lathe question #3 What the chuck!?

Posted: Sat Oct 20, 2012 2:02 pm

by Jos

Ocelot55 wrote:@Wayne: I have no clue what you mean. Are you saying mount the chuck onto the back plate, or mount a chuck in a chuck...seems a bit excessive.

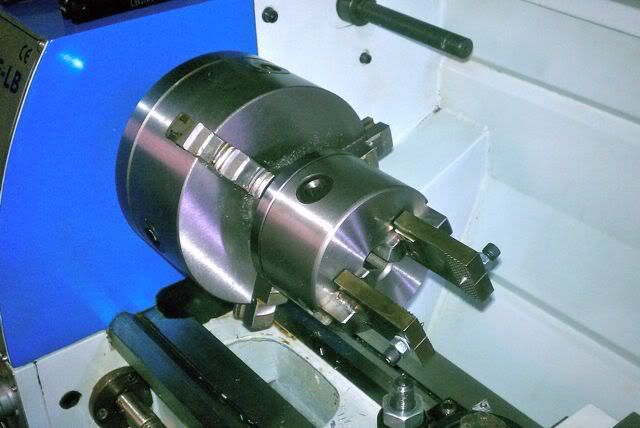

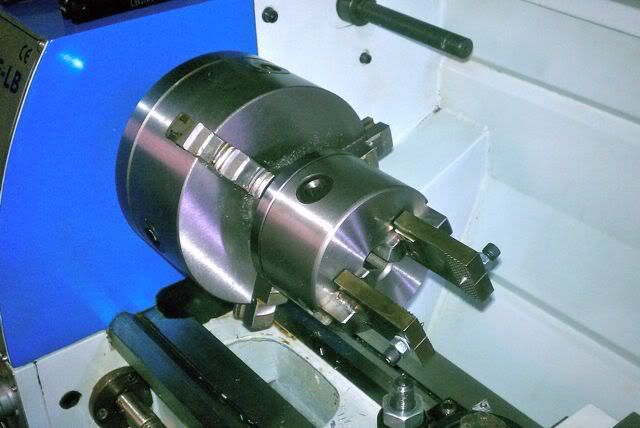

What Wayne meant, is this:

Good thing is, you keep your 3-jaw chuck - which is perfect for stem work - and can simply chuck up a specialized chuck for briar blocks in that, and you can change between these with no effort.

Jens

Re: Stupid lathe question #3 What the chuck!?

Posted: Sat Oct 20, 2012 2:19 pm

by Ocelot55

Wow, is that safe? Looks weird.

Re: Stupid lathe question #3 What the chuck!?

Posted: Sat Oct 20, 2012 3:58 pm

by Jos

Sure, why not ? The smaller chuck has a steel rod at its back side, which is chucked up perfectly tight in the bigger one ...

Jens

Re: Stupid lathe question #3 What the chuck!?

Posted: Sat Oct 20, 2012 9:36 pm

by Tyler

Ocelot55 wrote:Wow, is that safe? Looks weird.

For what we're doing, it fine.

Unless I'm mistaken that pic is of Jeff Gracik's rig, which should lend some credibility to the idea.

Re: Stupid lathe question #3 What the chuck!?

Posted: Sat Oct 20, 2012 10:42 pm

by wdteipen

Ocelot55 wrote:Wow, is that safe? Looks weird.

It's as safe as anything else you will do on a lathe. The setup Jos posted is a Trent Rudat chuck on a Precision Matthews metal lathe. Nate King has the exact same setup. I've used it and it works beautifully. The added benefit is that the chuck can be used on pretty much any lathe as long as you have a decent existing chuck.

Re: Stupid lathe question #3 What the chuck!?

Posted: Sun Oct 21, 2012 4:38 am

by caskwith

How hard can you clamp down on a piece of briar with this kind of chuck? THe thing that worries me when I see one is how far away the clamp point is from the scroll of the chuck which is doing all the work. Seems like it would bow out at the end of the jaws or put a lot of pressure on the chuck jaw slides.