Page 1 of 1

My winter project

Posted: Sun Apr 07, 2013 6:31 pm

by oklahoma red

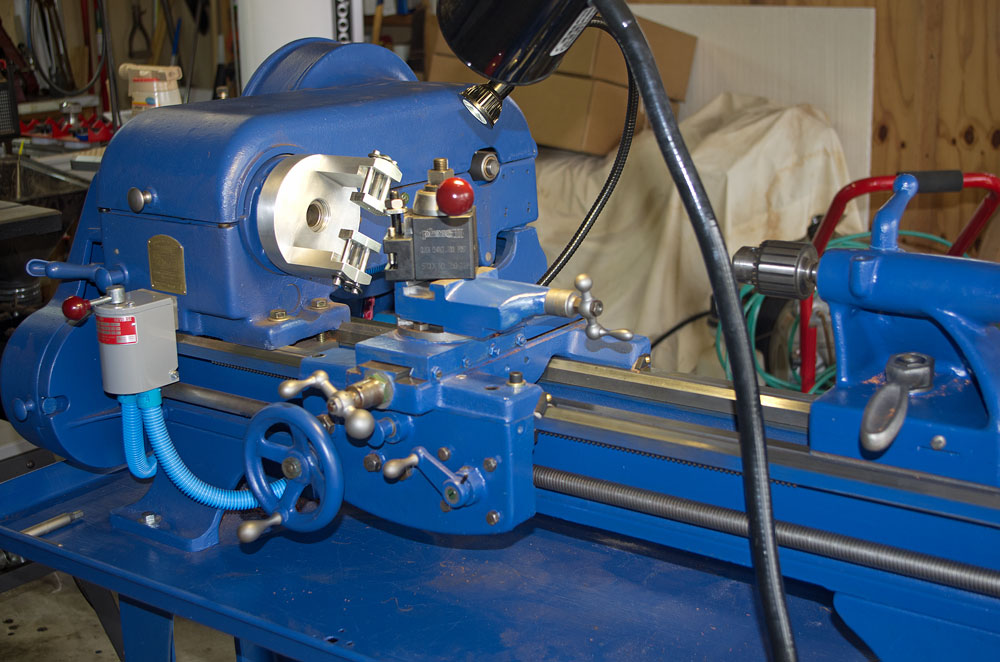

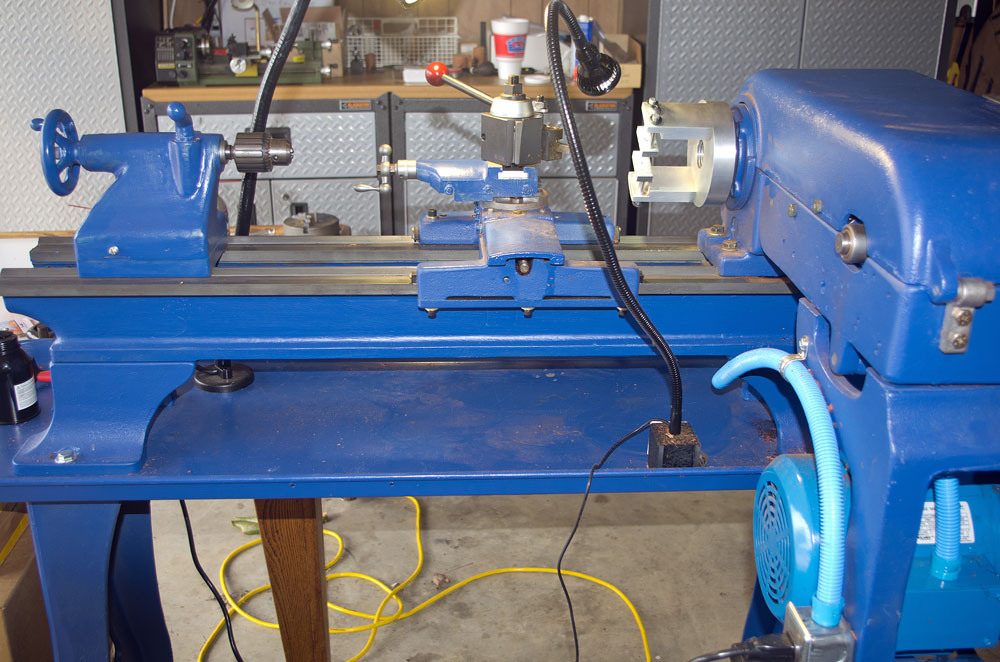

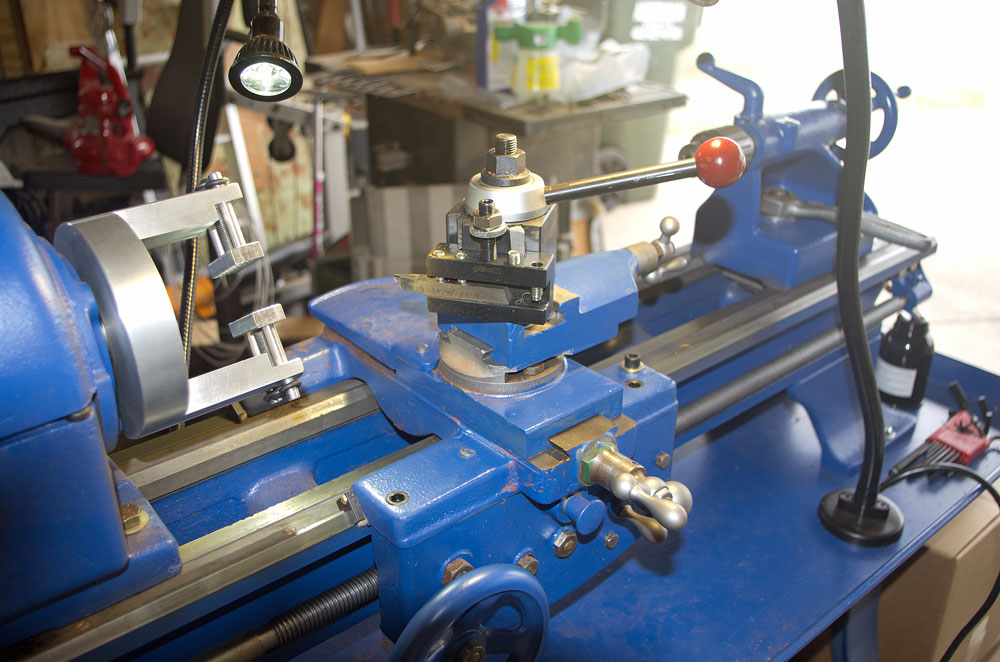

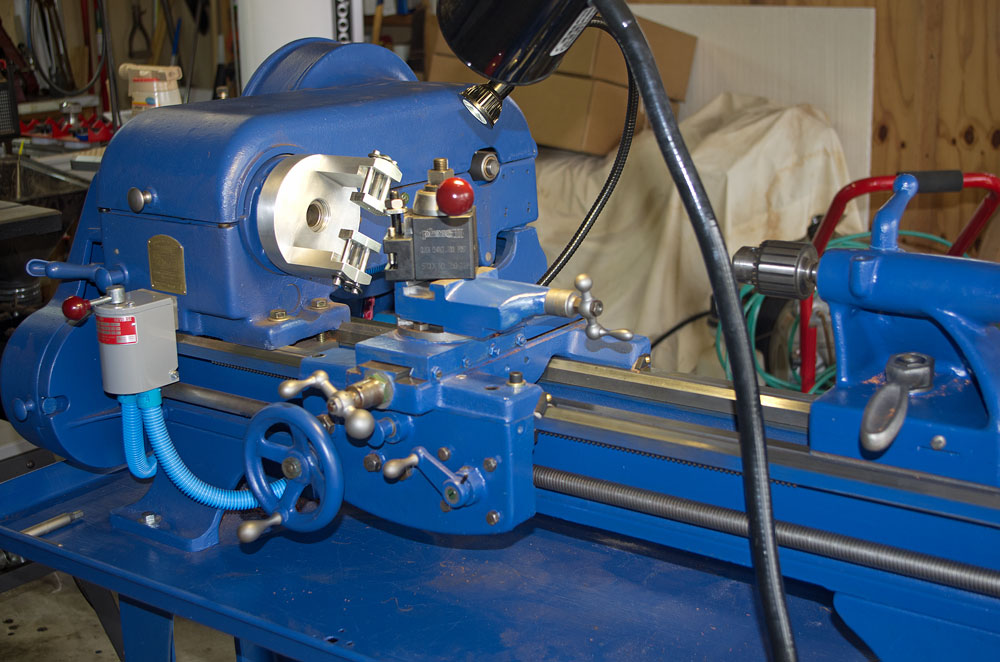

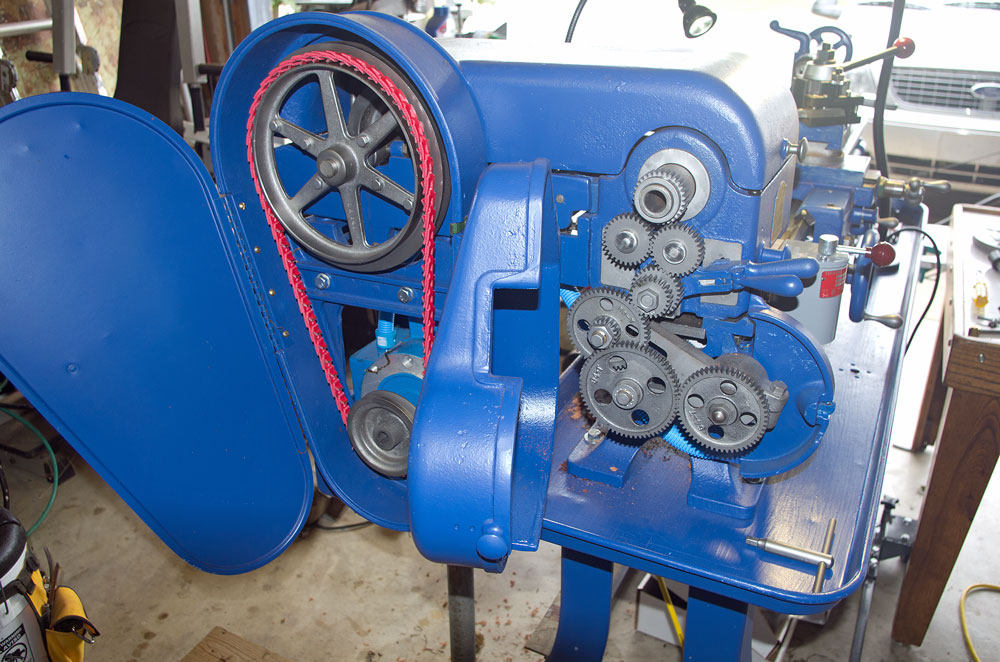

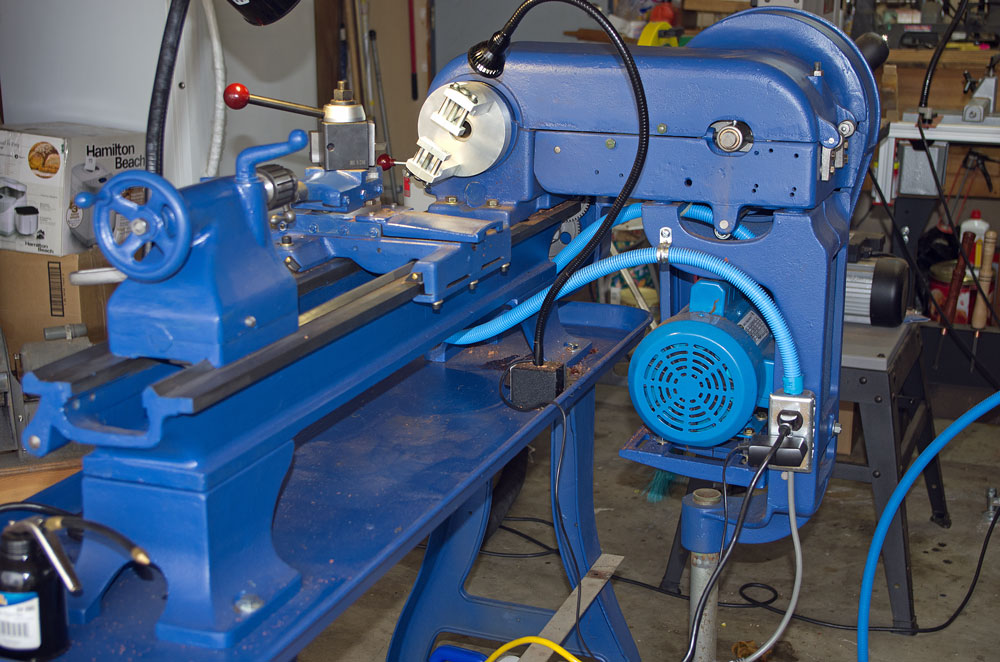

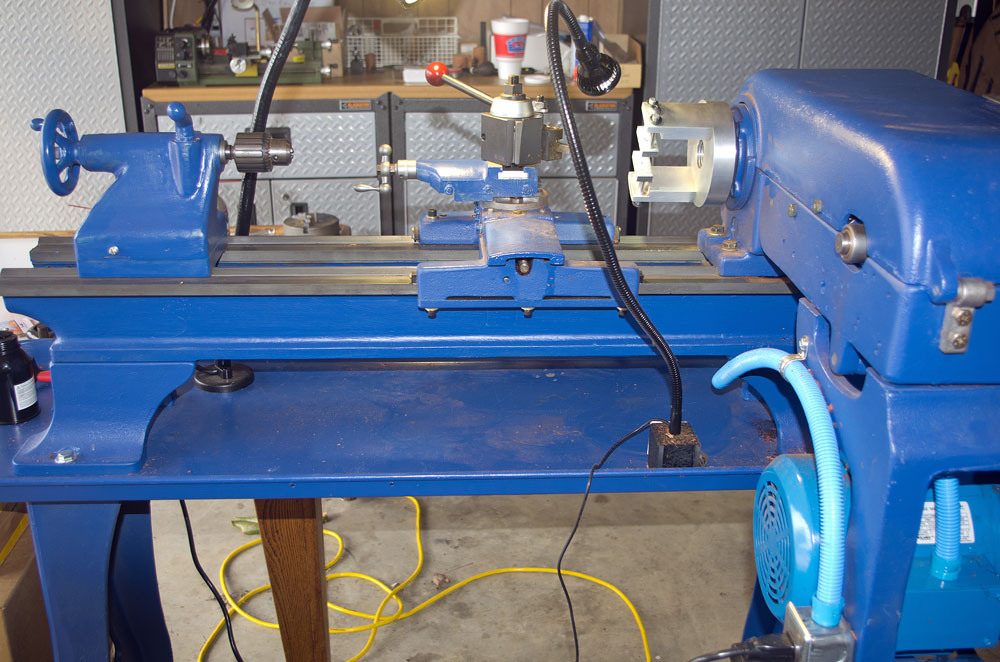

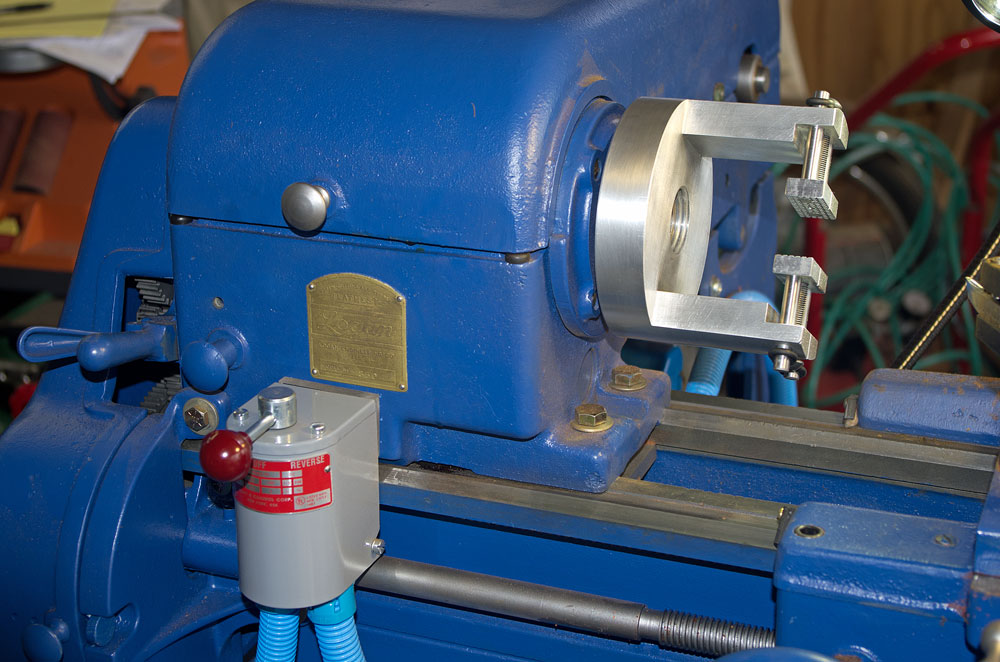

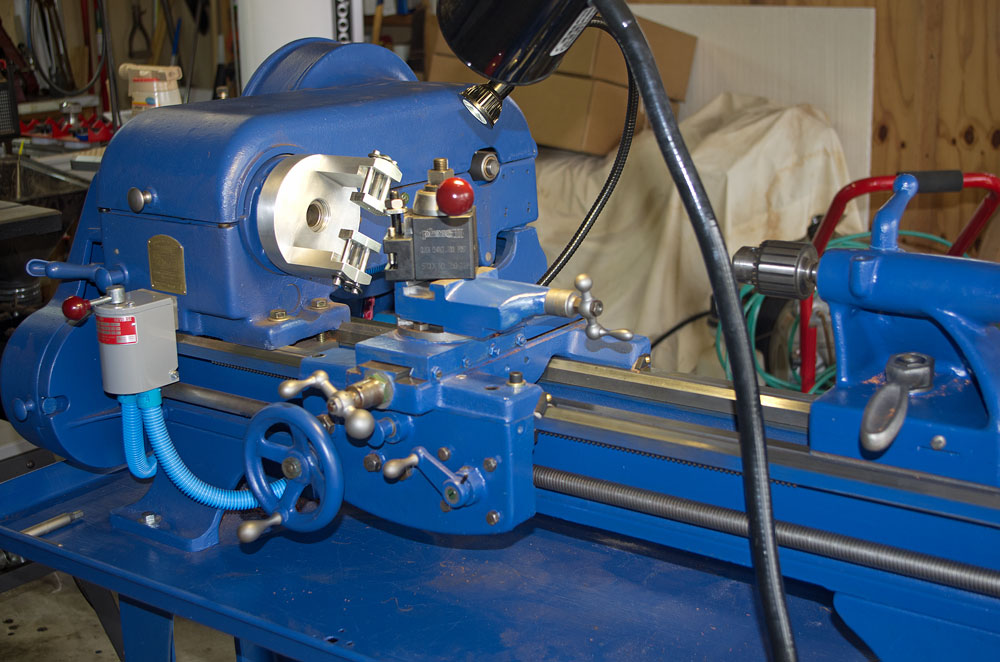

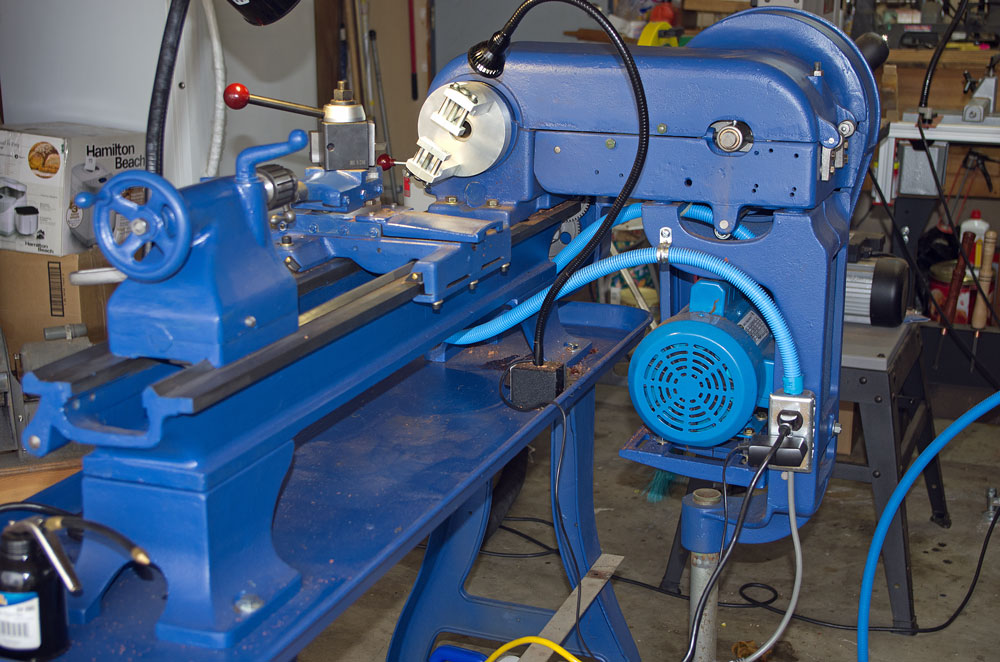

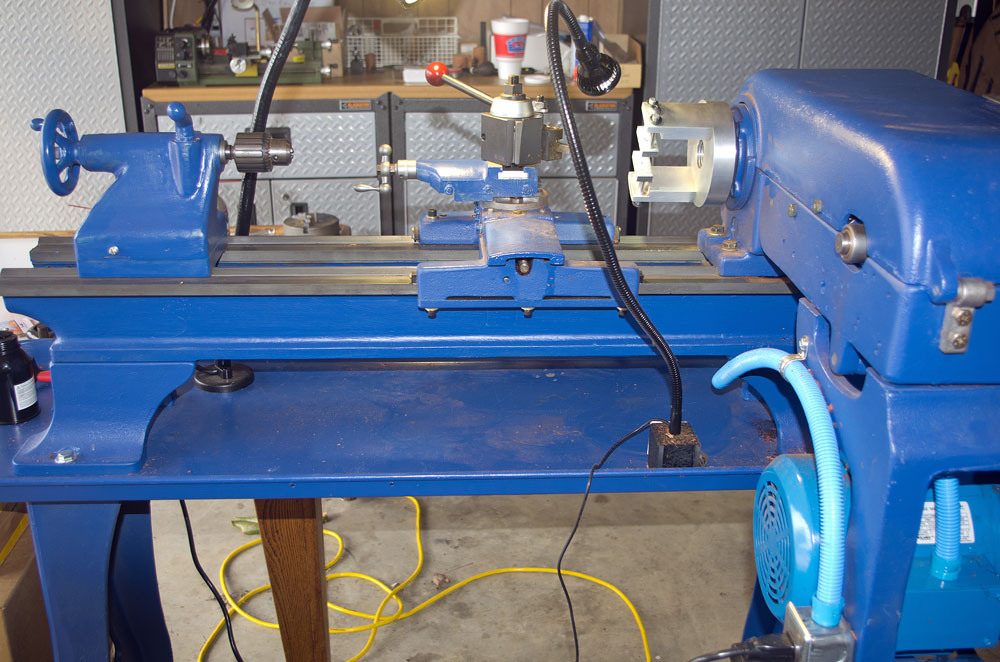

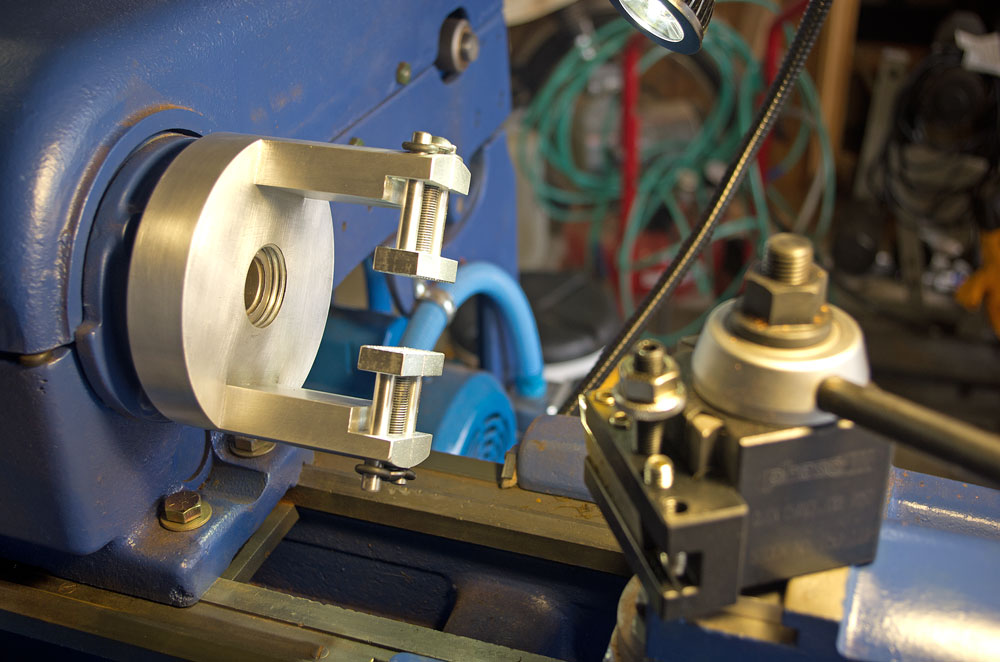

Well, it only took about 9 months but the Blue Wasp is up and running. I've decided to convert the bearings on the counter-shaft from bronze bushings to sealed needle bearings to stop the constant oil drip from the porous bronze. That and a new leg cross brace are about all that is left to totally finish it.

I've misplaced the "before" pics unfortunately. I'll keep looking. It was a pukey green and had not been cleaned in several decades. It now has new spindle bearings and numerous other new components. It runs quite smooth tho probably not as smooth as a vintage Myford. I put them in a class by themselves.

All that being said I believe this will be an excellent pipe lathe.

Please forgive the sorry condition of my garage. The rest of the family has been shoveling their crap into it all winter. Major spring cleaning is coming (dyno-mite!!)

Chas.

Re: My winter project

Posted: Sun Apr 07, 2013 6:57 pm

by wisemanpipes

chas,

how much time and money did you put into this beauty. i was thinking about getting a logan. whats your thoughts on a logan over a myford ml7 i think it is. both needs restoration.

anyway sweet machine!

Re: My winter project

Posted: Sun Apr 07, 2013 7:49 pm

by Alden

Thats a fine looking machine you got there.

Re: My winter project

Posted: Sun Apr 07, 2013 9:38 pm

by pipeguy

Nicely done Sir, It's very blue

Re: My winter project

Posted: Sun Apr 07, 2013 9:40 pm

by LatakiaLover

So, what are we talkin', here? Fifty, sixty bucks for the machine and a couple hours to spiff it up? At least it's easy to move around. A $25 hand truck from Wal-Mart and you'll be good to go.

Re: My winter project

Posted: Sun Apr 07, 2013 10:54 pm

by oklahoma red

chas,

how much time and money did you put into this beauty. i was thinking about getting a logan. whats your thoughts on a logan over a myford ml7 i think it is. both needs restoration.

anyway sweet machine!

Almost 9 months to the day that I rolled it into my garage. Actual hands on time was not that long really. Unfortunately I have to work for a living so that took precedence. Lost track of what I put into it. Suffice to say it was far less than say a new Precision Mathews which seems to be the favored Chi-Com machine.

The Myfords are nice. The Brits have always had a passion for precision lathes. They are rather uncommon on this side of the pond. Chris Askwith can tell you more than I about getting parts to restore one. That's the beauty of the Logans. New and used parts are readily available.

Chas.

Re: My winter project

Posted: Sun Apr 07, 2013 11:01 pm

by oklahoma red

Thats a fine looking machine you got there.

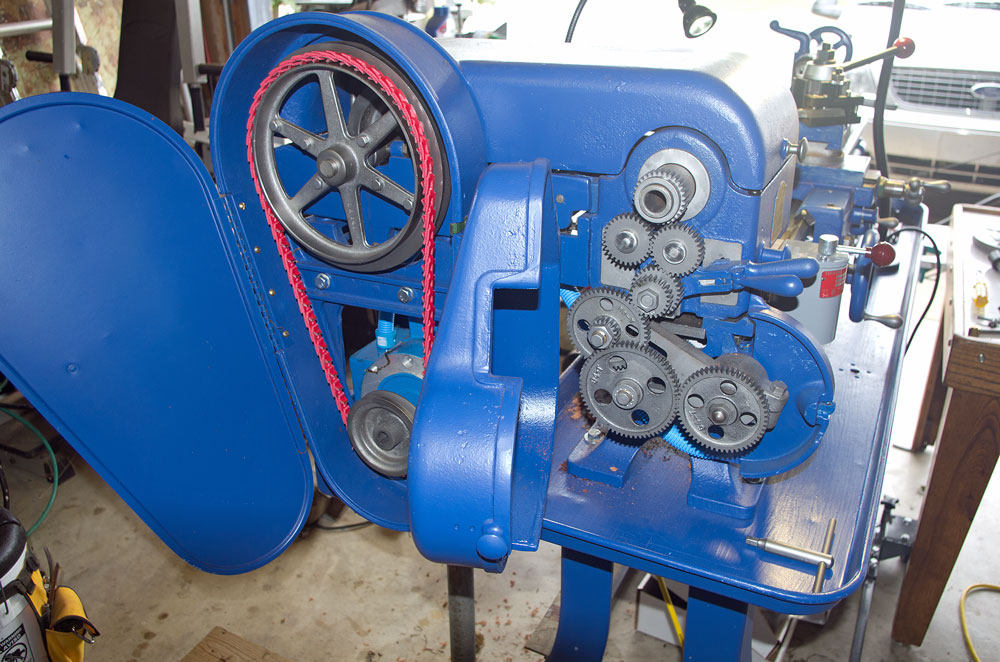

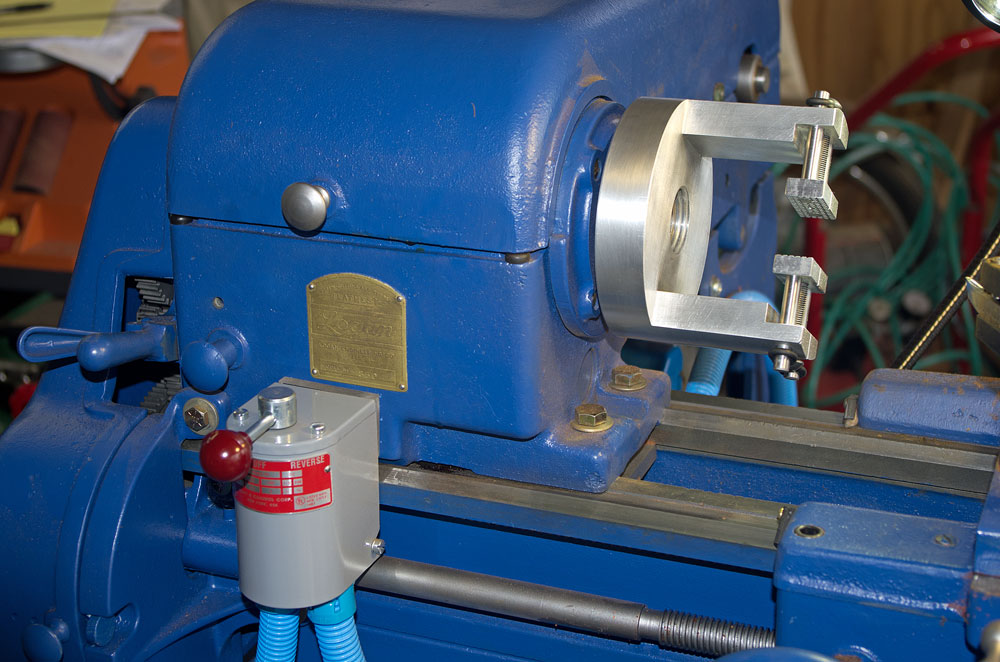

Thank you very much. It was an enjoyable project. It works quite well for being 71 years old. I'm anxious to get the needle bearing conversion on the counter-shaft done. The bearings were less than $10.00 each. They have to run on a precision ground shaft. I got a piece of Thomson linear shaft for less than $25.00. I have a friend with precision CNC lathes and he is making the journals for me gratis. When I get all the pieces together I'll put up some pics for any other Logan owners that might be interested.

Chas.

Re: My winter project

Posted: Sun Apr 07, 2013 11:08 pm

by oklahoma red

Nicely done Sir, It's very blue

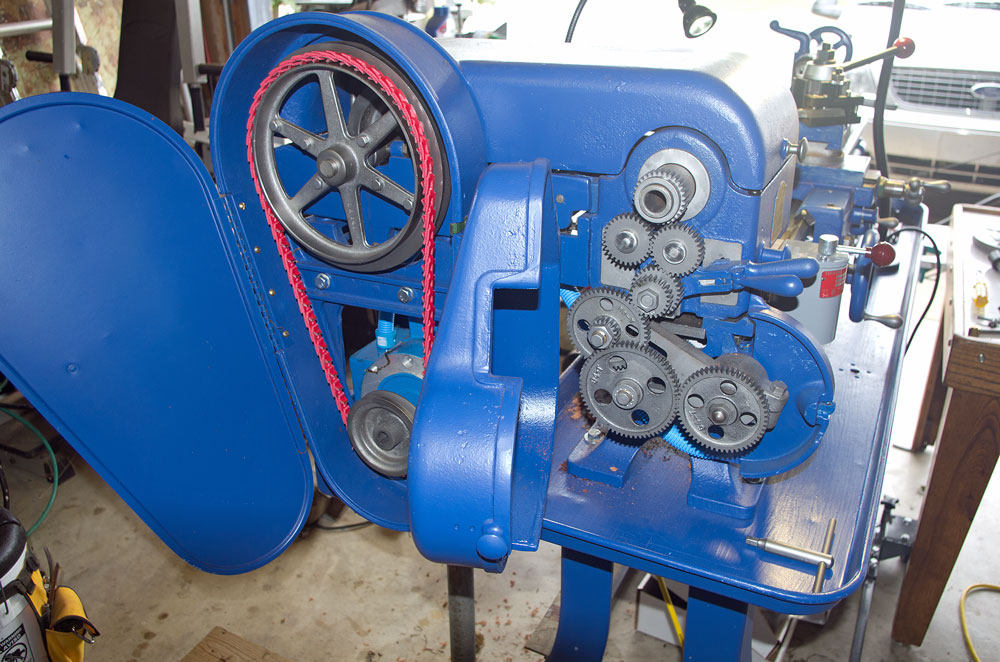

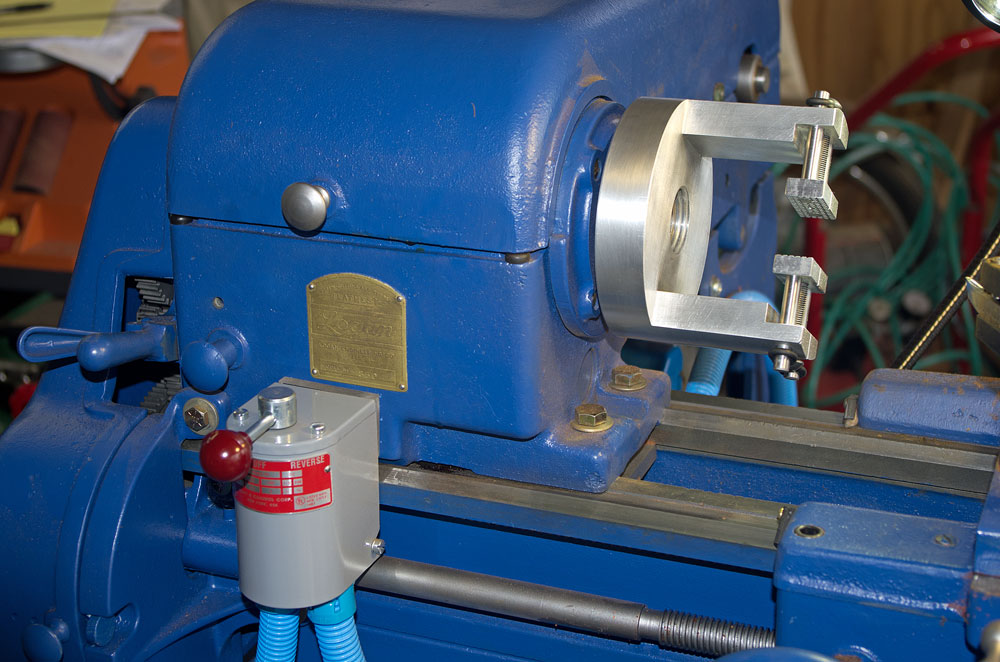

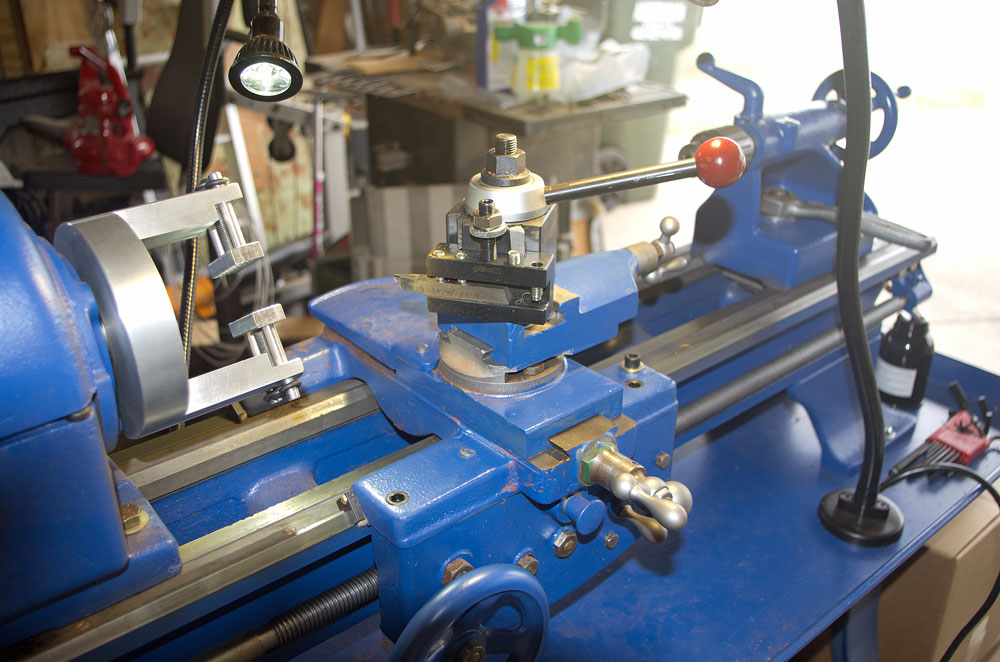

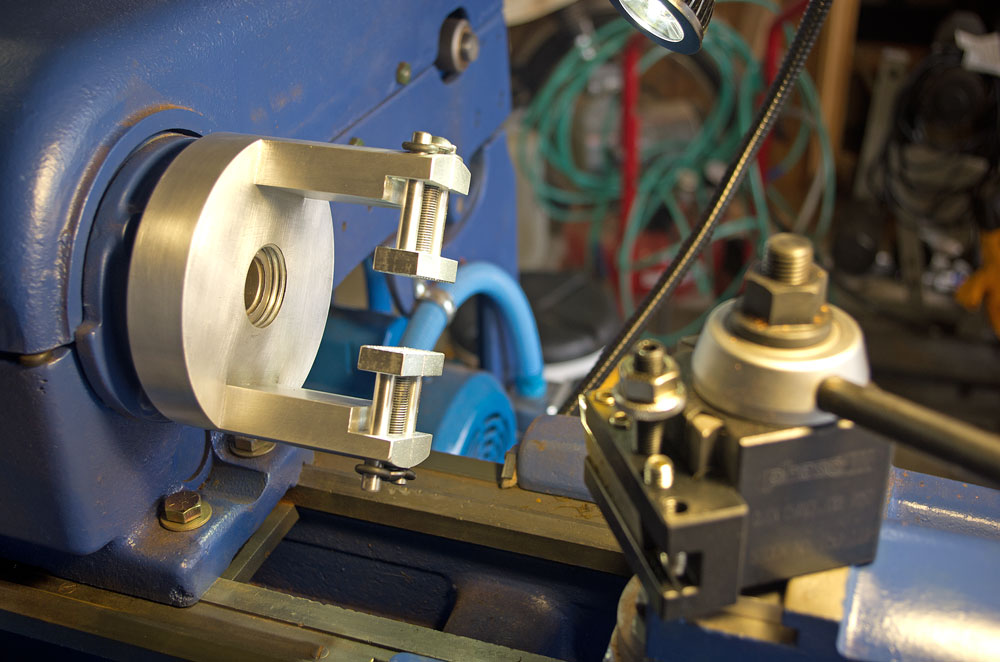

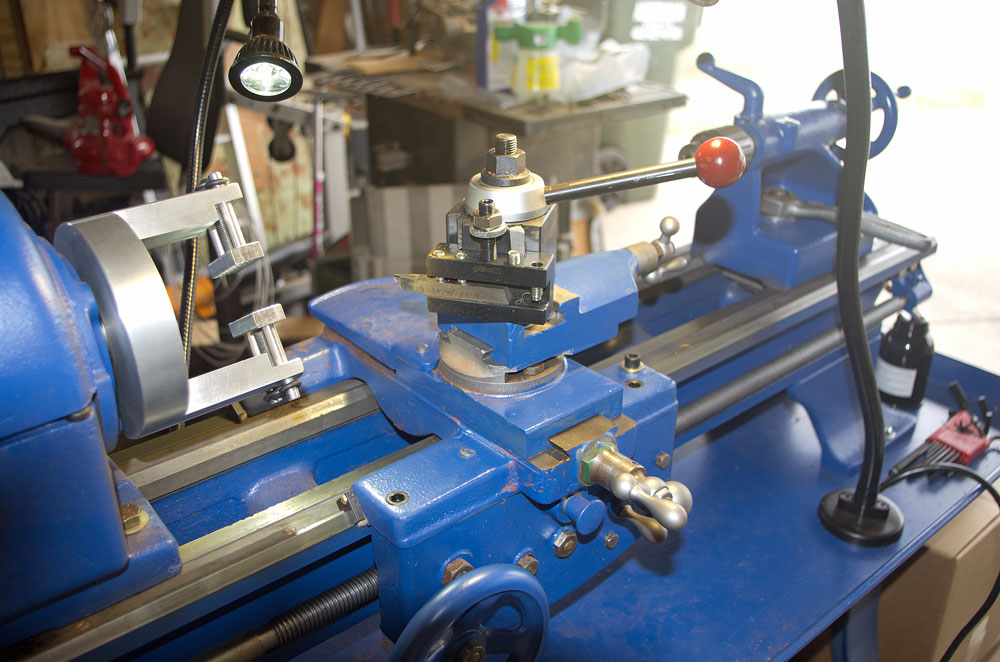

Thanks. I did manage to sneak in another color or two. Note the red Fenner drive belt and gray motor switch.

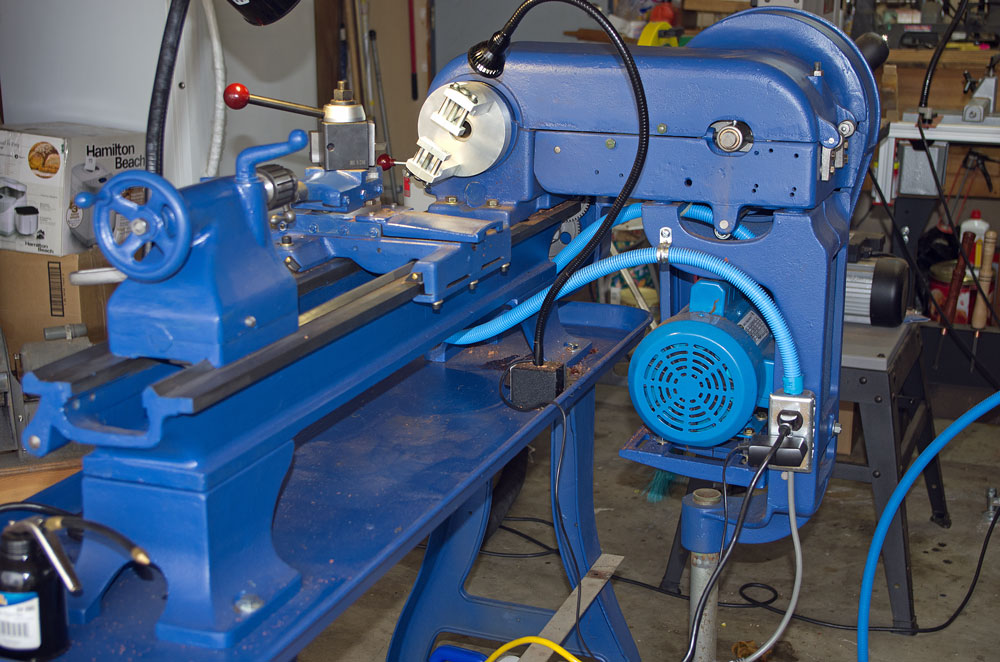

First part was stripping, cleaning and re-painting. Chose the color as a whim. Got a new motor and when it arrived surprise, surprise. It was almost the same color as what I painted the iron. Came time to wire it and I went to Lowes and ta-dah! The flex conduit and fittings were blue, tho a lighter shade. We'll call this my Blue Period.

Chas.

Re: My winter project

Posted: Sun Apr 07, 2013 11:15 pm

by oklahoma red

So, what are we talkin', here? Fifty, sixty bucks for the machine and a couple hours to spiff it up? At least it's easy to move around. A $25 hand truck from Wal-Mart and you'll be good to go.

Actually, a hand truck from Wally World will not be necessary. The pics don't show it but I've got it setting on a heavy duty roller machine base. Once I get the crap cleaned out of my garage I'll be able to move it where ever I want it. I'm going to put similar bases under my Delta lathe and my band saw. I might even be able to get one of my vehicles back in the garage.

Chas.

Re: My winter project

Posted: Sun Apr 07, 2013 11:26 pm

by LatakiaLover

oklahoma red wrote:So, what are we talkin', here? Fifty, sixty bucks for the machine and a couple hours to spiff it up? At least it's easy to move around. A $25 hand truck from Wal-Mart and you'll be good to go.

Actually, a hand truck from Wally World will not be necessary. The pics don't show it but I've got it setting on a heavy duty roller machine base. Once I get the crap cleaned out of my garage I'll be able to move it where ever I want it. I'm going to put similar bases under my Delta lathe and my band saw. I might even be able to get one of my vehicles back in the garage.

Chas.

Cool.

Since residential garage and basement floors are never level by design, do you use shims or something to level things up when it's parked? For that matter, is being level essential or just a good idea on a machine that size? (As in, somewhere between a Unimat and commercial multi-ton stuff professional leveling and set-up is a must. What's the threshold?)

Re: My winter project

Posted: Sun Apr 07, 2013 11:52 pm

by oklahoma red

Since residential garage and basement floors are never level by design, do you use shims or something to level things up when it's parked? For that matter, is being level essential or just a good idea on a machine that size? (As in, somewhere between a Unimat and commercial multi-ton stuff professional leveling and set-up is a must. What's the threshold?)

I moved it around to various places to find a "sweet spot" in the floor. I borrowed a precision machinist's level to check it. I got lucky and found a spot that required no shimming.

Being level is important but not ultra critical in what we do since so much of the work is performed fairly close to the headstock. The degree of level is most important perpendicular to the bed in a horizontal plane. Being off-bubble in the Y axis can put a twist in the bed which will show up in turning long items between centers. It will manifest itself as a taper. Obviously the bigger (longer) the lathe the more the need for precision level. Unless your floor is a real stinker you should not have problems getting it level. If it is going to stay in one place all the time there are a lot of leveling feet on the market from screw type to adjustable wedges.

Chas.

Re: My winter project

Posted: Mon Apr 08, 2013 3:20 am

by caskwith

I never bothered to level my lathe and it has never been a problem for me.

Looking very nice anyway. Who made your chuck?

Re: My winter project

Posted: Mon Apr 08, 2013 4:43 am

by Charl

Wow! Really is a nice job. I don't know if I'll ever have the patience for that.

Btw, Myford's are sweet! Although, if I have a choice between a ML7 and super 7, I'll definitely go for the Super 7.

Re: My winter project

Posted: Mon Apr 08, 2013 5:06 am

by rijks

Great machine for making great pipes !

Best regards,

Re: My winter project

Posted: Mon Apr 08, 2013 7:05 am

by jogilli

i've looked at it three times.. nice little set up you've picked up...

james

Re: My winter project

Posted: Mon Apr 08, 2013 8:43 am

by oklahoma red

I never bothered to level my lathe and it has never been a problem for me.

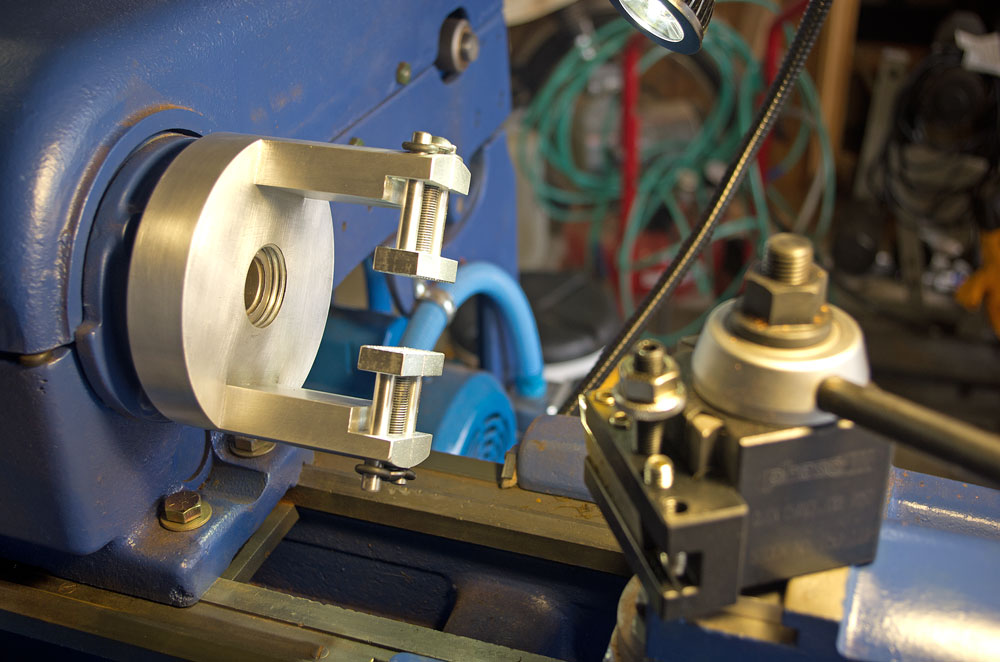

Looking very nice anyway. Who made your chuck?

Thanks.

One also has to consider the design and quality of the bed. Some are bound to be more resistant to twisting than others.

Chuck was made by Ken Lamb. I have another one of his that has the boss on the bottom so as to be held in a scroll chuck. I opted for the direct thread-on this time to decrease the overhang. He kindly offered me a trade-in deal but I decided to keep the original in case I want to run two lathes at once.

Chas.

Re: My winter project

Posted: Mon Apr 08, 2013 9:19 am

by oklahoma red

Thanks to all for your comments. For those of you looking for a lathe and wind up with a Logan and need any assistance I'll be glad to help in any way I can.

Chas.

Re: My winter project

Posted: Mon Apr 08, 2013 10:43 am

by pipedreamer

That is one good looking MACHINE...CARS we don't need no stinkin cars. You must feel pretty good. Nice job.

Re: My winter project

Posted: Mon Apr 08, 2013 11:21 am

by wisemanpipes

oklahoma red wrote:Thanks to all for your comments. For those of you looking for a lathe and wind up with a Logan and need any assistance I'll be glad to help in any way I can.

Chas.

im leaning toward a logan, chas, so might just take you up on that offer!

Re: My winter project

Posted: Thu Apr 11, 2013 8:36 am

by billiard

Great looking hunk of metal, congrats and good work!