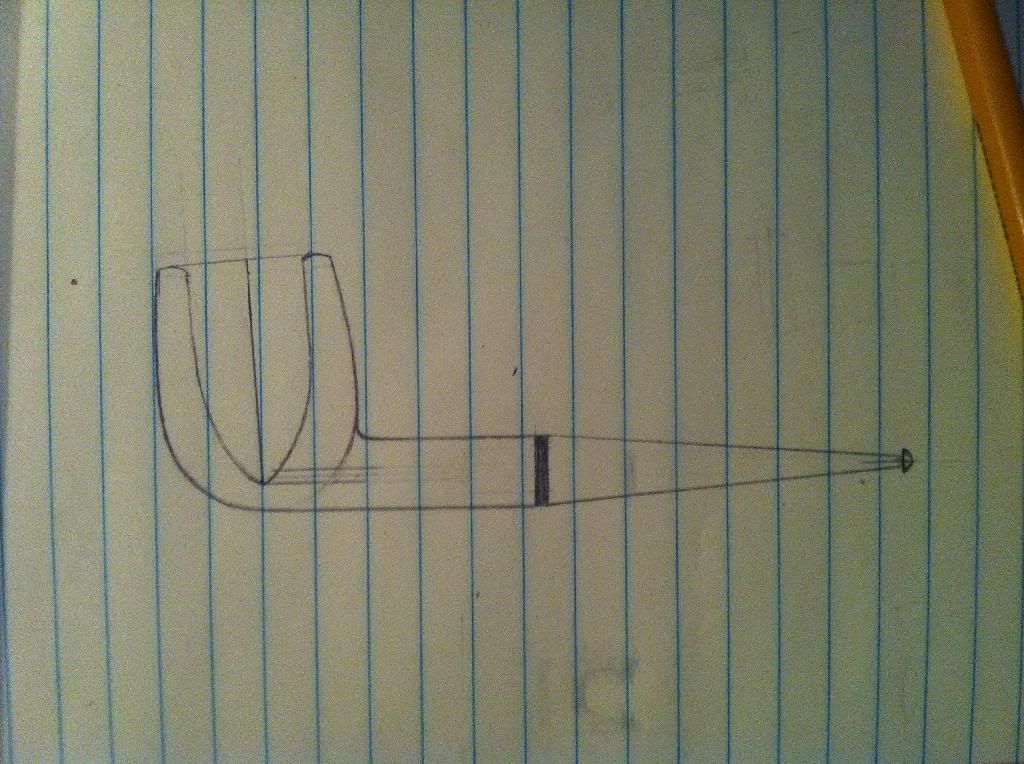

I'm getting ready to make my first billiard and I'm hoping you all can give me a little clarification on some issues that I'm not quite clear on. I have been reading through the critiques on as many billiards as I can find in the gallery and that has proven extremely helpful. The problem is, I only have a couple of blocks left and precious little money to order more if I screw em up. Besides the the lack of funds, they both look to have great grain and I want to do them justice if I can. In addition to my questions, I'm attaching a sketch I just did of what I think a billiard should be. I'd really appreciate it if you all could tell me where I'm missing the mark as to a classical billiard. Thanks in advance!!

1. I have one plateaux block and one cross grain. Both look like great blocks and should make nice pipes. My question is, would a cross grain billiard be somehow considered less of a "classical" billiard, or is either grain pattern acceptable?

2. I'm still a little confused about the shank. From the profile, should the top and bottom lines of the shank be perfectly parallel or have a slight taper?

3. Regarding the stem/shank juncture. Again, from the profile, should the change in angle be a crisp change or should I ease that transition? If it should be eased, do I start that on the shank or on the stem?

4. Would a half saddle stem still be acceptable for a classic billiard, or should they always be tapered stems?