Thanks, Jeff

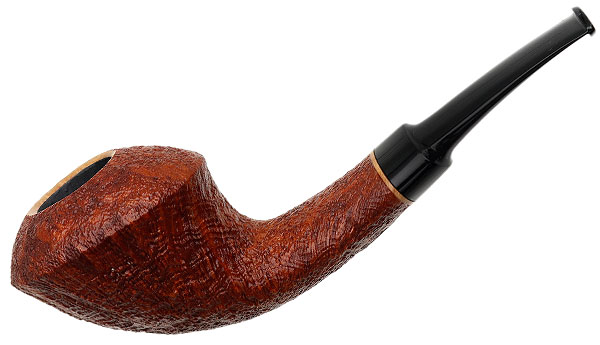

- Length: 4.58 in

- Weight: 2.00 oz.

- Bowl Height: 1.74 in.

- Chamber Depth: 1.25 in.

- Chamber Diameter: 0.75 in.

- Outside Diameter: 1.75 in

- Stem Material: German Ebonite

Damn, that's something I never considered - I've just been eyeballing mine and then looking at the Abe/Davidson examples mine look too thick on the sides by comparison (probably). Now I'm going to have to frantically check when I get home.scotties22 wrote: I personally try to make the side of the stem (at the button) be as wide as the slot. This isn't a very good pic of that, but you can see the sides are well defined.

Here's the thread: viewtopic.php?f=10&t=8600scotties22 wrote:Right behind your button isn't very crisp either. That and your button need to be a bit taller are making the stem look fat as well. I can't find the link (didn't look very hard), but watch George's video about sanding and finishing the stem right behind the button.

You should really try to wash it on a regular basis. I've head that helpsRickB wrote:All I want is for my crease to shine like mad

scotties22 wrote:You should really try to wash it on a regular basis. I've head that helpsRickB wrote:All I want is for my crease to shine like mad

scotties22 wrote: I personally try to make the side of the stem (at the button) be as wide as the slot. This isn't a very good pic of that, but you can see the sides are well defined.

Correctseamonster wrote:scotties22 wrote: I personally try to make the side of the stem (at the button) be as wide as the slot. This isn't a very good pic of that, but you can see the sides are well defined.

I think I know what you mean, but just so it's clear in my mind:

Your aim is to make the thickness of the stem SIDE at the button is the same as how tall the opening of the slot is? Meaning, roughly, a millimeter and a half or so?