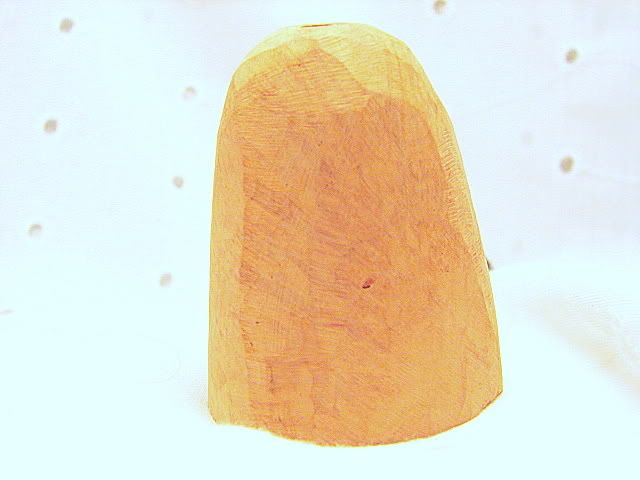

Never hit a big one like that on the back. So there might be others to tell if it is worth the effort at all, or if this size causes other issues than the look that would be "hidden" by the rustication.

As a matter of taste, I don't like pipes with small rustications just on and around some smaller flaws. Partial rustication like that tells just that there was a flaw. It's like plastering some dings on your car's hood without spraying the whole thing with new paint. I have seen some pipes like that when restoring estates. Rather nice shapes, but with these mini rusticated areas. Quite ugly, I think.

Partial rustication of larger areas is a completely different thing. Those areas can bring contrast, shape and lines to the overall appearance that relly add somthing to it.

I have never tried partial rustication. I don't go for alcohol free alcoholic drinks either. It is either beer (mayber harder stuff, depending on the situation

)

or sparkling water (if I have to drive). But I never drank some alcohol free beer yet. I am not that much for the "in-betweens", allthough they can be interesting, as I said before. I tend to decide to go the one or the other way. Call me stubborn for neglecting the shades in between…

I would rusticate it completely.