Bulldog/Dublin on an undersized lathe

Posted: Wed Aug 04, 2021 4:25 pm

Cutting the top of a bulldog and the accent rings on a small lathe presents a challenge. There is not enough swing on my HF 8x12” metal lathe to use the traditional methods- pipe jaws (don’t have them on my 3 jaw chuck) or jam chuck working from the left (because the shank will not clear the saddle/tool post)

Below is presented a hybrid method- freehand approximation and then refinement on the lathe.

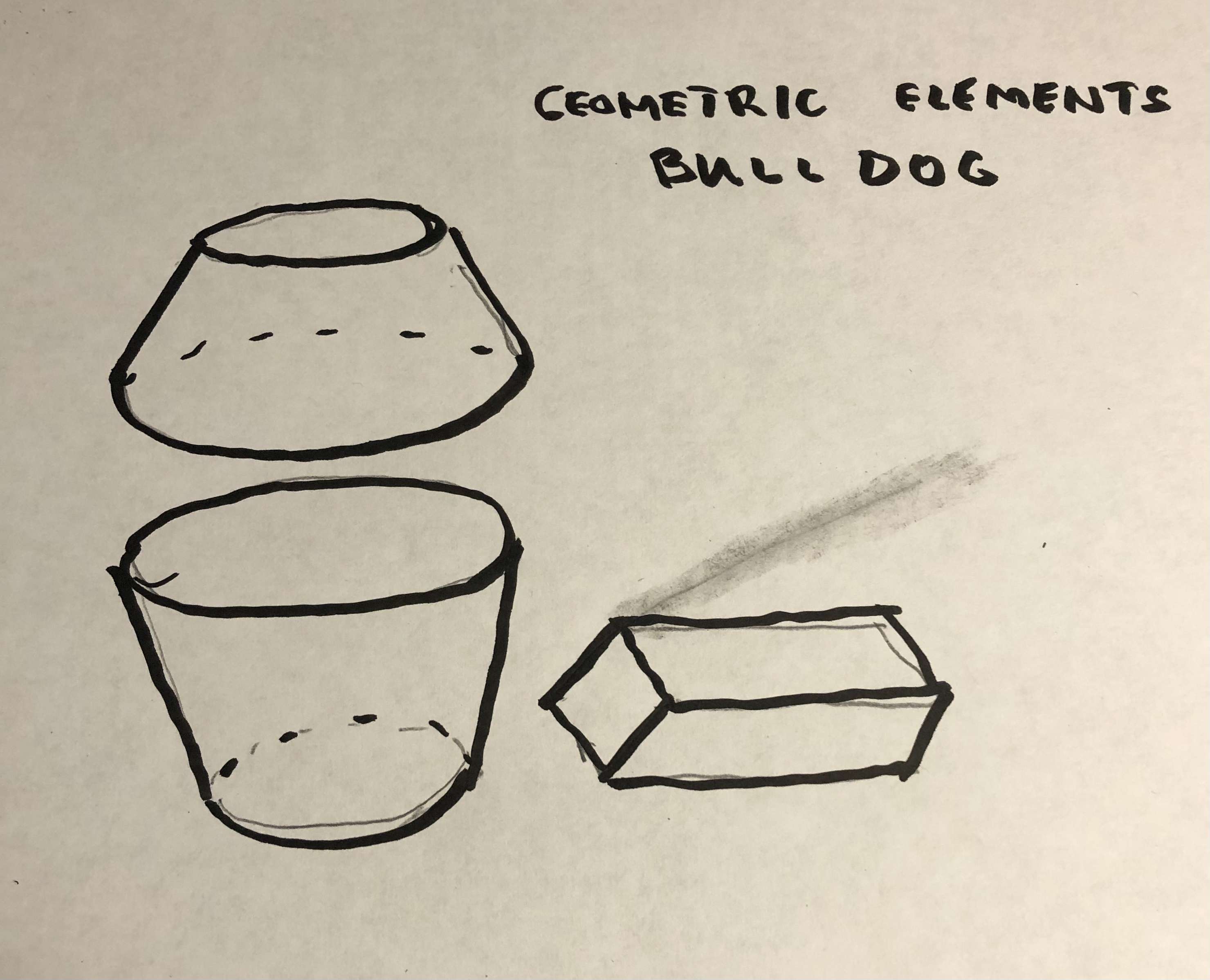

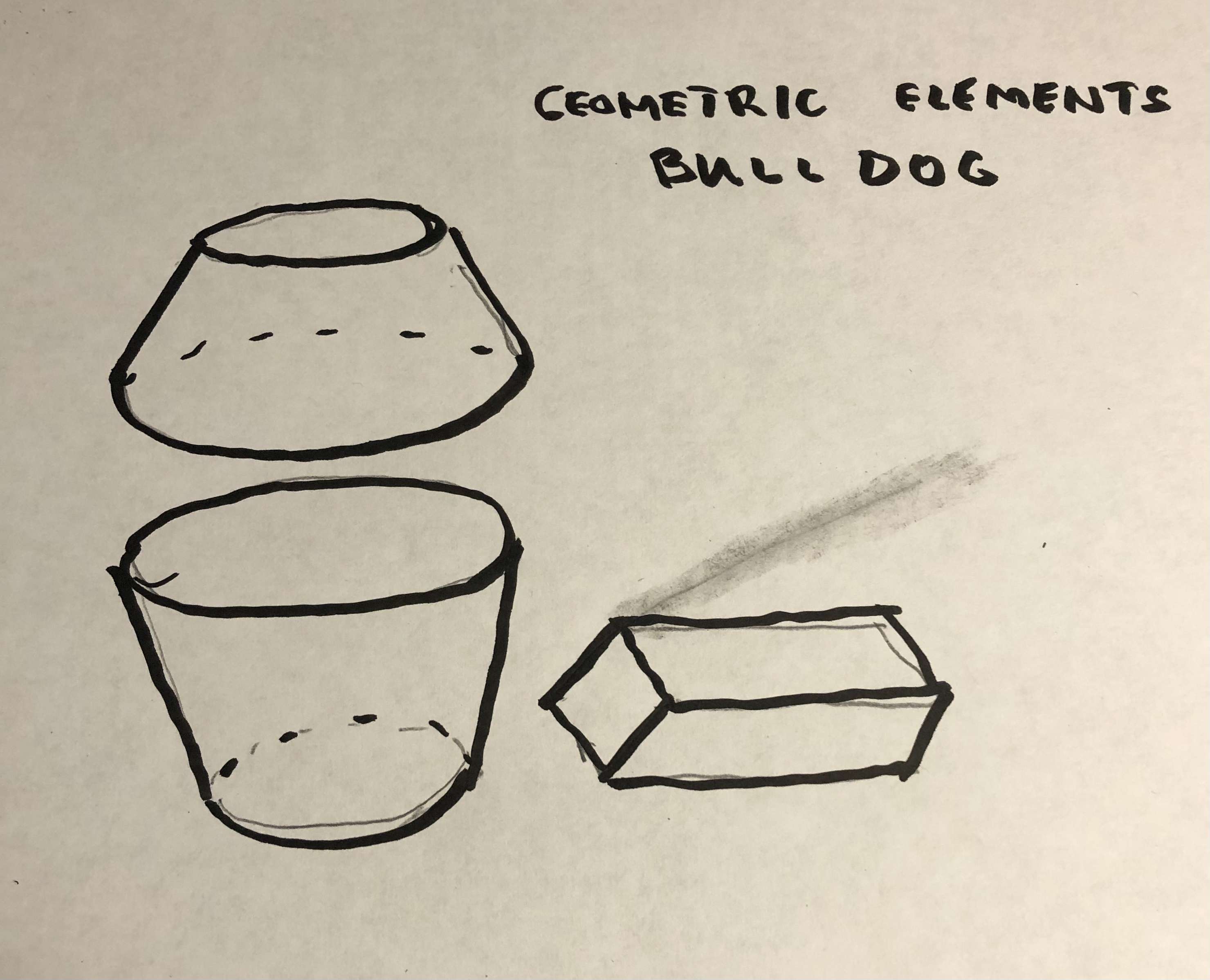

1) Determine the geometric elements of the shape.

2) approximate the shape freehand while cutting for grain and avoiding flaws.

a. The base cone is approximated along the rays of the grain

b. The shank begins to form-angled to avoid flaws.

c. The top cone is approximated and the diamond shank begins to develop.

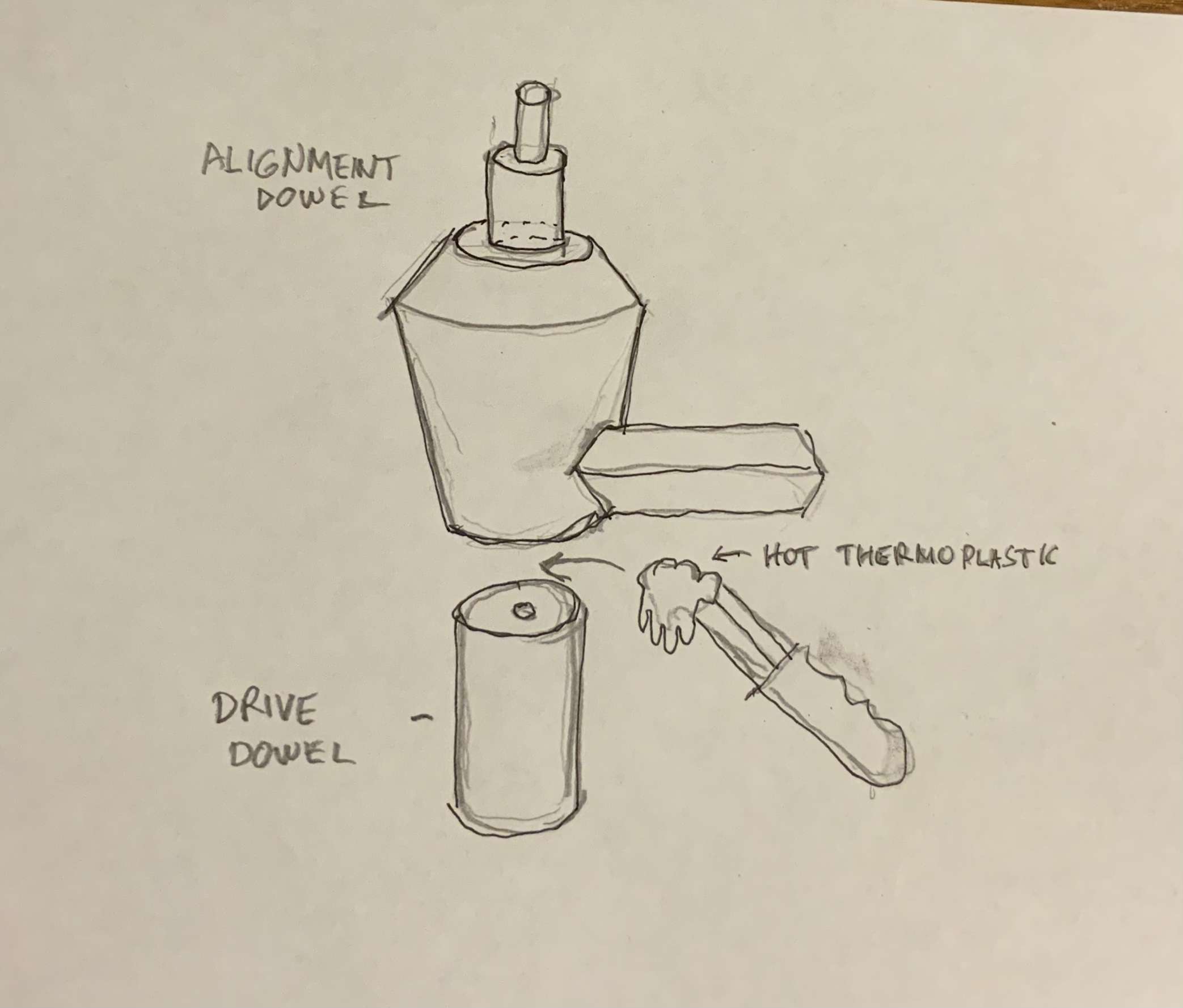

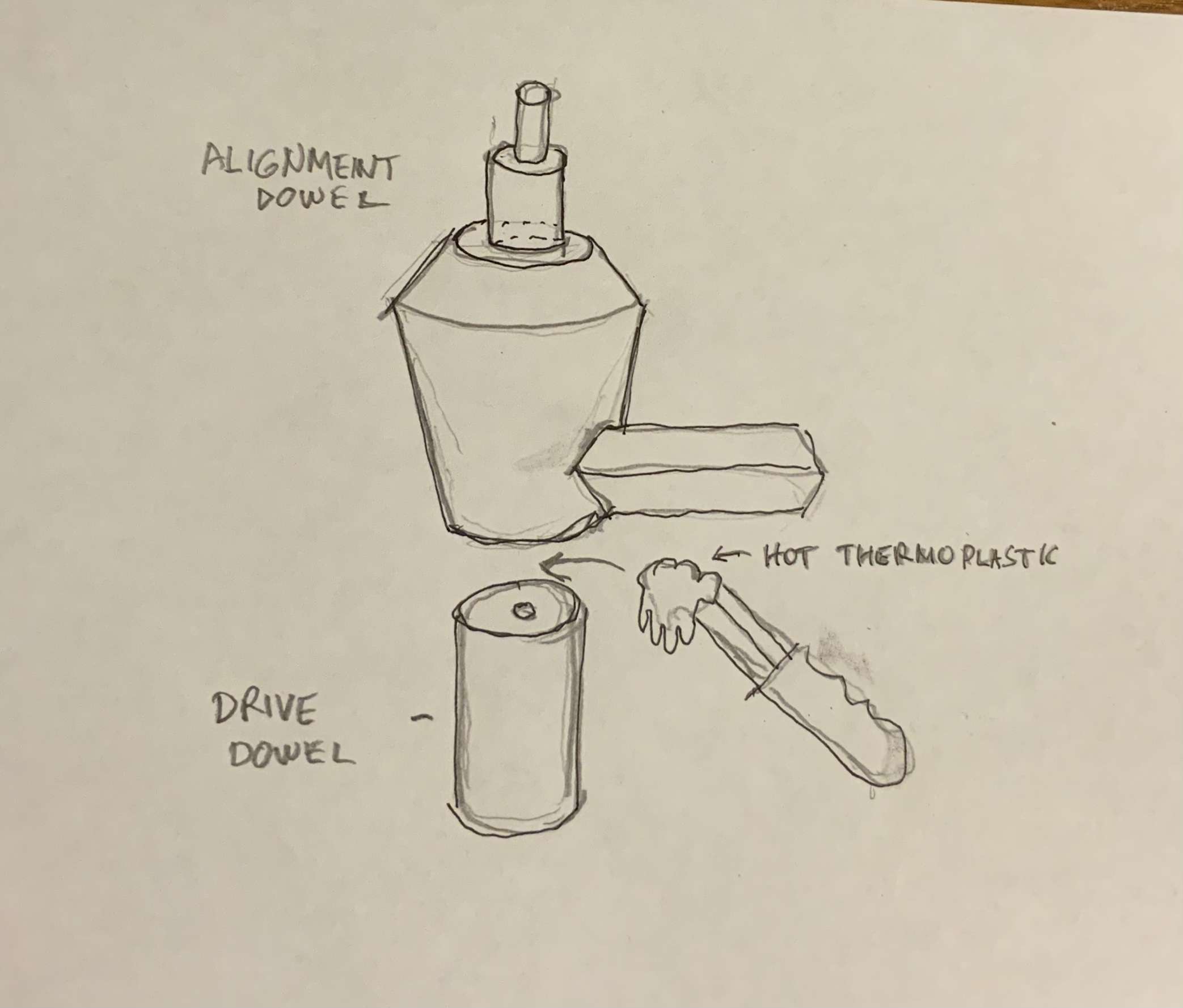

3) After freehand drilling using a modified freehand method, a “drive dowel” is attached to the stummel coaxial to the chamber. This will allow the stummel to be driven from the left and cut from the right while clearing the lathe bed

a. Diagram of drive dowel/stummel

b. An alignment dowel has been cut to fit coaxially in the chamber. The upper end is reduced to fit the quill chuck of the drill press

c. The drive dowel (trued and center drilled) is aligned on the drill press jig using the engagement pin of the jig and a pin chucked in the drill press.

d. Some melted thermo plastic is placed on top of the drive dowel and the alignment dowel/stummel lowered onto the melted plastic and held there until solid (2 minutes). I use a bungee to hold this down and do something else.

The photo below is of the assembly after turning. A turned and center drilled piece of Delrin has replaced the alignment dowel. This engages the live center of the tail stock.

4) The drive dowel is chucked in on the left, the Delrin plug is engaged with the live center, and the top of the bowl and accent rings are cut on the lathe. I used the “etch-a-sketch” method and my regular cutters for this, with some smoothing with files.

The accent rings were cut with the tool at the bottom of the photo. This was ground from a stock HSS tool.

5) When finished turning, the drive dowel and thermoplastic are broken loose from the stummel. This was a very strong bond- I could have used about 1/3rd as much plastic. I had to clamp the. dowel in the vise and partially cut the plastic with a hammer and chisel.

6) The stem rod is fitted and shaped along with the shank- rotating 90 degrees to achieve a symmetrical diamond.

7) Finished Bulldog/Dublin I did put a small (2mm) bend in the stem.

DocAitch

Below is presented a hybrid method- freehand approximation and then refinement on the lathe.

1) Determine the geometric elements of the shape.

2) approximate the shape freehand while cutting for grain and avoiding flaws.

a. The base cone is approximated along the rays of the grain

b. The shank begins to form-angled to avoid flaws.

c. The top cone is approximated and the diamond shank begins to develop.

3) After freehand drilling using a modified freehand method, a “drive dowel” is attached to the stummel coaxial to the chamber. This will allow the stummel to be driven from the left and cut from the right while clearing the lathe bed

a. Diagram of drive dowel/stummel

b. An alignment dowel has been cut to fit coaxially in the chamber. The upper end is reduced to fit the quill chuck of the drill press

c. The drive dowel (trued and center drilled) is aligned on the drill press jig using the engagement pin of the jig and a pin chucked in the drill press.

d. Some melted thermo plastic is placed on top of the drive dowel and the alignment dowel/stummel lowered onto the melted plastic and held there until solid (2 minutes). I use a bungee to hold this down and do something else.

The photo below is of the assembly after turning. A turned and center drilled piece of Delrin has replaced the alignment dowel. This engages the live center of the tail stock.

4) The drive dowel is chucked in on the left, the Delrin plug is engaged with the live center, and the top of the bowl and accent rings are cut on the lathe. I used the “etch-a-sketch” method and my regular cutters for this, with some smoothing with files.

The accent rings were cut with the tool at the bottom of the photo. This was ground from a stock HSS tool.

5) When finished turning, the drive dowel and thermoplastic are broken loose from the stummel. This was a very strong bond- I could have used about 1/3rd as much plastic. I had to clamp the. dowel in the vise and partially cut the plastic with a hammer and chisel.

6) The stem rod is fitted and shaped along with the shank- rotating 90 degrees to achieve a symmetrical diamond.

7) Finished Bulldog/Dublin I did put a small (2mm) bend in the stem.

DocAitch