Page 1 of 1

Clamping a premolded stem

Posted: Mon Mar 03, 2014 2:32 pm

by randyhoguepipes

Does anyone have a suggestion on how to clamp the button end of a premolded stem while turning the tenon? I am using a Taig lathe for the stems.

Thanks,

Randy

Re: Clamping a premolded stem

Posted: Mon Mar 03, 2014 2:38 pm

by LatakiaLover

A few years ago, some guy made and marketed a chuckable, concave cone widget with a slot that was designed for the purpose, but I don't know how well they worked or if they're still available.

Re: Clamping a premolded stem

Posted: Mon Mar 03, 2014 3:06 pm

by caskwith

Was it Kim Kendall that made them?

Re: Clamping a premolded stem

Posted: Mon Mar 03, 2014 3:22 pm

by Sasquatch

Depending on how you are set up for the lathe, if you can chuck a flat screwdriver tip and slide a stem over that you can use that as a drive spur, or you could cut a slot in a plywood faceplate and insert the fishtail in that.

Re: Clamping a premolded stem

Posted: Mon Mar 03, 2014 3:38 pm

by Tyler

The Taig four-jaw self-centering chuck works pretty well for grabbing most pre-formed stems. That's how I used it in my pre-formed days.

Re: Clamping a premolded stem

Posted: Mon Mar 03, 2014 6:49 pm

by pipedreamer

Taig 4 jaw works great or eyeball it and cut some balsa to hold it and if you don' crank the jaws as tight as you can it will work on most stems.The spur thing SAS suggest works great also.Penn state industries makes a drive thingy for pens that would work.And thank you thingy is a word , just ask Scottie.

Re: Clamping a premolded stem

Posted: Mon Mar 03, 2014 11:22 pm

by wdteipen

If you drill your airway first you could use a pin gauge in the airway to turn down the tenon. Just put a live center on the button end to keep it centered.

Re: Clamping a premolded stem

Posted: Mon Mar 03, 2014 11:35 pm

by yachtexplorer

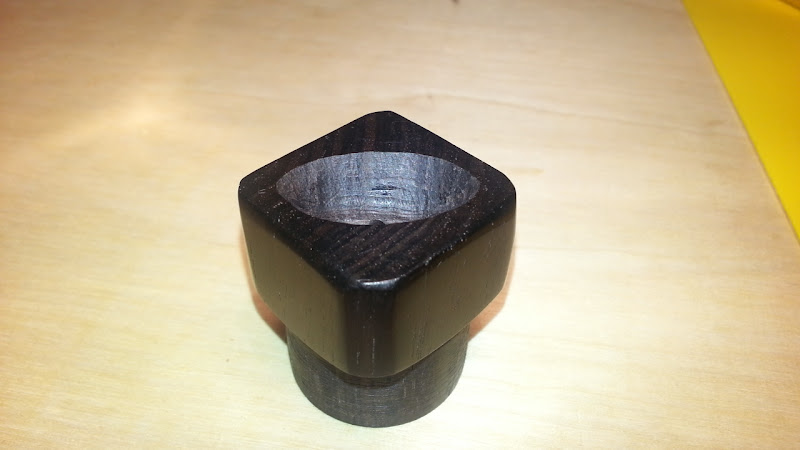

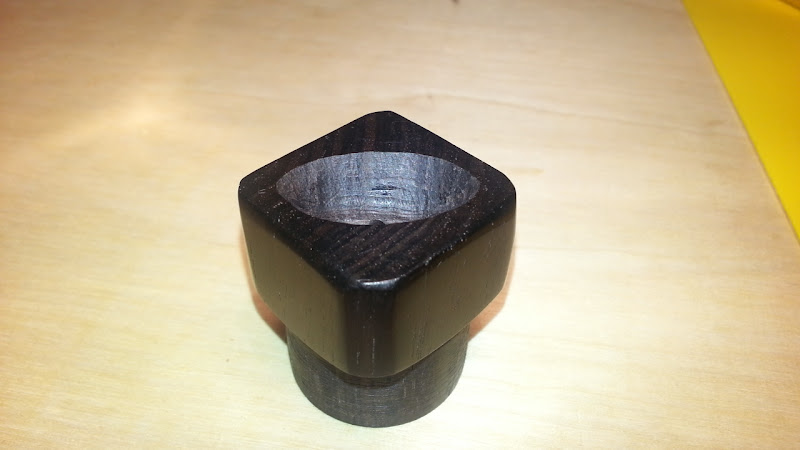

I created this stem chucking tool out of African blackwood. I turned the shank portion to fit in my headstock and then cut out an oval socket that tapers from a button size way beyond what I would ever make down to a trendy skinny button. I ground out the socket that receives the button using a Foredom going back and forth from the bench to the lathe until I had it perfectly centered using a dial guage. I span the stem between my tool and a live center allowing me to taper the stem and cut the tenon.

Re: Clamping a premolded stem

Posted: Mon Mar 03, 2014 11:39 pm

by scotties22

That is VERY nifty!

Re: Clamping a premolded stem

Posted: Tue Mar 04, 2014 6:00 pm

by CACooper

Greetings,

Learned how to make this from Paul Perri:

Bar stock aluminum, machine the cone in one end, slip on slotted chair/cane foot to prevent stem from spinning. Self centers the stem every time. Simple. A "why didn't I think of that" thing.

CACooper

Re: Clamping a premolded stem

Posted: Wed Mar 05, 2014 4:42 am

by caskwith

I am assuming very light cuts with these setups?

Re: Clamping a premolded stem

Posted: Wed Mar 05, 2014 3:47 pm

by Charl

Piece of alumimium rod, groove on one face to take button and a pin to keep the stem in place.

Makes sense?

Re: Clamping a premolded stem

Posted: Thu Mar 06, 2014 10:20 am

by Sasquatch

caskwith wrote:I am assuming very light cuts with these setups?

IF you have a taper in the "socket" end, the piece sits quite securely.

Re: Clamping a premolded stem

Posted: Thu Mar 06, 2014 12:26 pm

by caskwith

I was thinking more that if the cutter dug in too deeply from a heavy cut then you might twist off the button?

Re: Clamping a premolded stem

Posted: Thu Mar 06, 2014 12:44 pm

by oklahoma red

Piece of alumimium rod, groove on one face to take button and a pin to keep the stem in place.

Makes sense?

Do you pre-bore the airway hole at the button to a specific size first? My experience has been that the airways in molded stems are all over the place size-wise. Or do you have several of these with different size pins (or an interchangeable pin system)?

Chas.

Re: Clamping a premolded stem

Posted: Fri Mar 07, 2014 2:59 am

by Charl

It's been years since I last used pre-molds, but way back I only had one size pin.

It worked a treat. When it broke while turning, because of digging in, it normally was at the tenon side.

Re: Clamping a premolded stem

Posted: Mon Mar 10, 2014 4:03 pm

by randyhoguepipes

Thank you for your suggestions. These were great ideas!

Randy

Re: Clamping a premolded stem

Posted: Tue Apr 29, 2014 1:26 pm

by fastredx

I saw CA's Paul Perri tool somewhere and sent pics of it to a friend who is a better machinist than I. He made one for me and for himself. Works great! I've done quite a few stem replacements since getting it.