chucks

chucks

What is the best way to hold the stummel in the lathe for drilling and shaping ? Which type of chuck is what I mean, a three jaw four jaw i don't know. Also once its in there whats the best way to center it. How well do four jaw self centering chucks work ?

Re: chucks

You might want to scribe centre lines on the faces of the chuck jaws.buster wrote:Also once its in there whats the best way to center it. How well do four jaw self centering chucks work ?

Regards,

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Tano, it might be a good idea to make a backing plate for your 4-jaw instead of counting on the threaded rod in the 3-jaw as an adaptor. It's an admirable piece of field expediency, and I'm sure it works -- I can't tell if you turned the threads off the part in the 3-jaw -- but I think reducing the length of your rotating assembly yields less vibration, better accuracy, and more safety. That's just me, though, you're probably a tool and die maker.

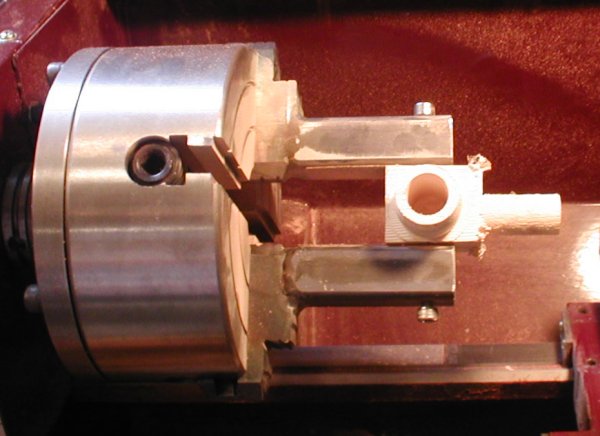

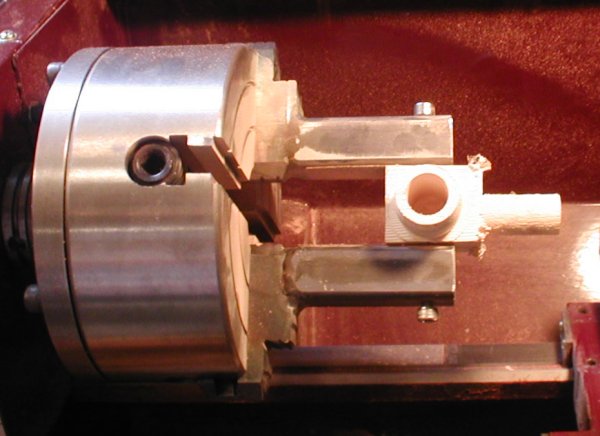

I prefer a four jaw independent with two jaws removed and in my case I've modified the remaining jaws with extensions and locating pins to facilitate alignment between the tobacco chamber and the draft hole. I have always had a heck of a time getting blocks perfectly square, and on occasion, it's been handy to be able to locate my drilling off center. If I'm chucking a block it's easier and more accurate for me to get the block somewhat square as opposed to perfectly square, then lay out my drilling, center punch where the chamber and draft hole intersect, and location for my mortise angle if it's different, such as for most of my bent pipes. I also center punch for the drill bit. Then I can just chuck up the block according to the locating pins and align it for drilling by using two chuck keys (one for each jaw) and moving the entire block captured in the chuck until I've aligned the drill to my punch marks for drilling.

My rig is a home brew version of the chuck J.T. Cooke and several others use, pictured here with a pipe test stummel:

Unless I'm also doing some turning I'm most often drilling freehand (after shaping) these days, but I still find the above rig very handy for traditional shapes, and anything requiring any turning on the lathe.

Ken Lamb and Trent Rudat both make something similar. The one pictured on Trent's site looks like a self centering version (scroll chuck), but I bet he would make an independent one too:

http://www.lambpipes.com/pipemakingtools.htm

http://www.briarpipetooling.com/

My rig is a home brew version of the chuck J.T. Cooke and several others use, pictured here with a pipe test stummel:

Unless I'm also doing some turning I'm most often drilling freehand (after shaping) these days, but I still find the above rig very handy for traditional shapes, and anything requiring any turning on the lathe.

Ken Lamb and Trent Rudat both make something similar. The one pictured on Trent's site looks like a self centering version (scroll chuck), but I bet he would make an independent one too:

http://www.lambpipes.com/pipemakingtools.htm

http://www.briarpipetooling.com/

Scott E. Thile

Collector, smoker, and aspiring pipemaker.

http://sethilepipes.com

Sysop: http://pipedia.org

---------------------

Collector, smoker, and aspiring pipemaker.

http://sethilepipes.com

Sysop: http://pipedia.org

---------------------