Hi there, my name is Greg, and I've been smoking a pipe off and on for almost 20 years, since the tender age of 17

Had been lurking for a while, trying to decide if this was a hobby that I wanted to try. The decision was made clear on my birthday when I discovered that due to my own dumb self, I had broken my one and only pipe (Manhall freehand, that I had inherited from a friend). The stem had broken off inside the pipe

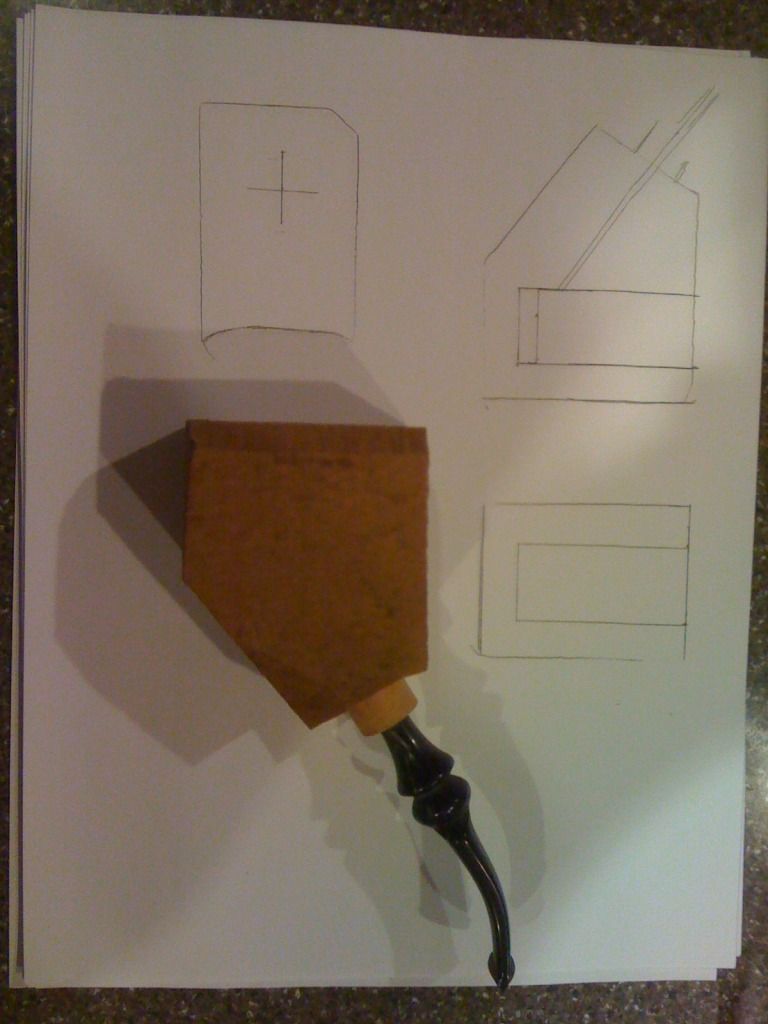

I ordered a pre-drilled kit from Pimo, and it arrived super fast. I didn't want to just start cutting into it though, so I picked up a couple pieces of hard wood to practice shaping on. Since the kit was the only "pipe" I had, I decided to start breaking the bowl in while working on a design. People look at you weird when you smoke a pipe kit... Spent two weeks going through tons of ideas on how to cut/shape the pipe. Every time I think I had it figured out, I'd tack up the picture for a day and see what I thought, then ball it up and throw it in the trash. Finally decided on a design that I was happy with, and drew out the shape on the briar. Called the pipe shop after the 3rd week and was told my pipe had sat at the shop for 2 weeks before being sent off for repairs, and it would be "a couple more weeks" till it came back

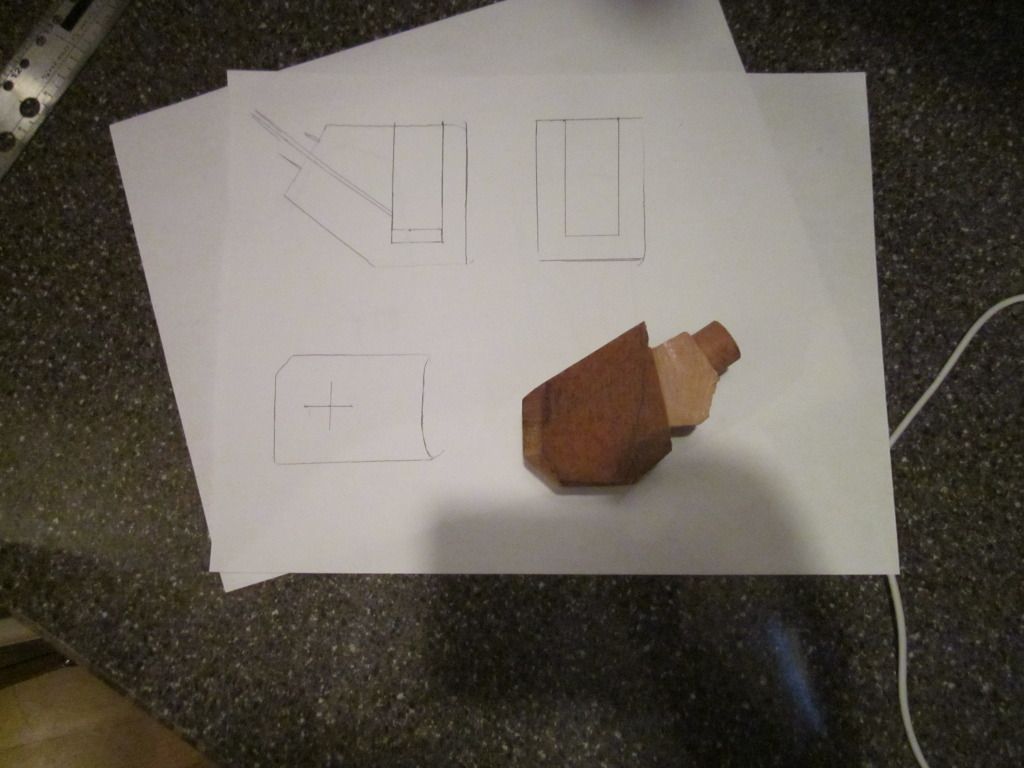

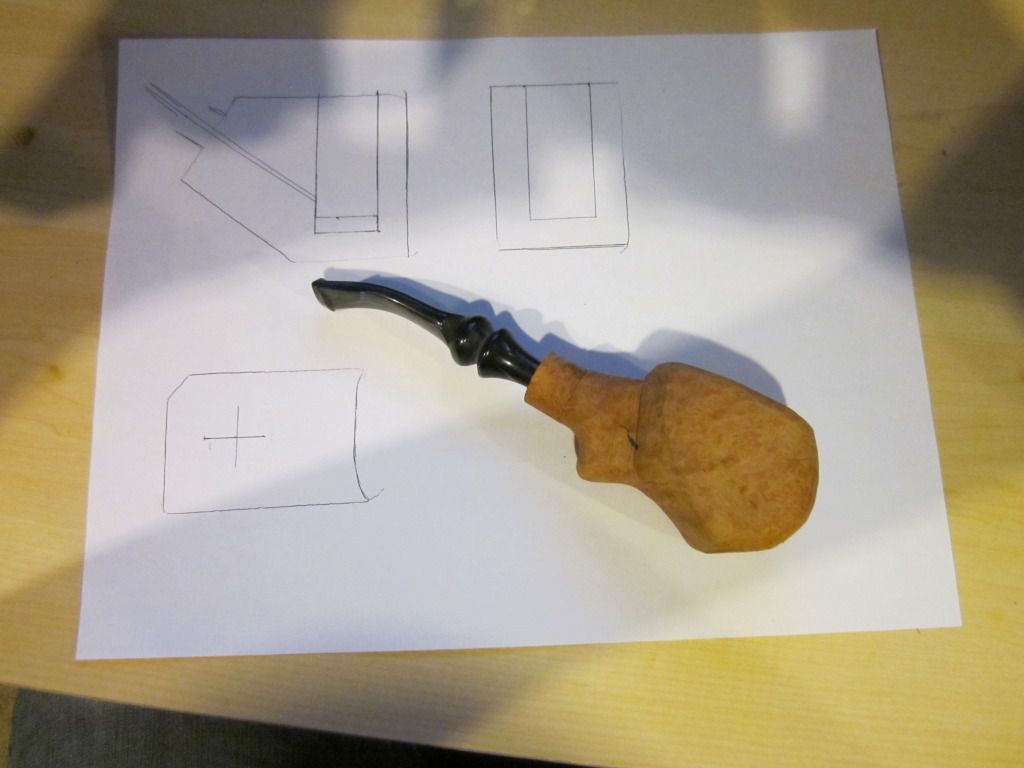

So tonight I finally made my rough cuts in the briar, using advice that's been posted in many threads about leaving room when making cuts, and I'm really liking how the shape is coming along! The briar is a lot easier to cut than some of the exotic hardwood "turning blocks" I picked up (thankfully!), but still slow going when doing cuts with a coping saw. I have a dremel, a belt sander, and a handful of files for the next step, as well as access to a nicely equipped wood shop. I am not expecting an awe inspiring final product, I'll be happy with something that fits nicely in my hand and doesn't look like my 5 year old made it. Also when it comes time to stain it, I'm pretty sure I'm going to go with a weird color. I'm thinking blue.

If you made it this far, thanks for reading! Hope to have this pipe finished in a week or two, and will post it in the gallery when the time comes.